MAGAZINE: LED attributes for accurate modeling: An optical designer’s wish list

Attribute 1: Near-field light distribution

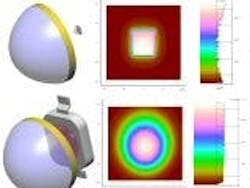

One detail that is consistently omitted when modeling LED systems is the accurate representation of the LED’s near-field light distribution (for example, at a distances less than roughly 10 times the size of the source). Of course, some optical designs, such as task lighting, can be accurately modeled without taking the near-field light distribution into account. A task light is often simply an LED shining onto a flat surface. There are no obstructions between the source and its distant target; therefore, the near-field light distribution need not be considered for this scenario. However, if a lens is placed in front of the LED that focuses the die onto the same surface, the near-field light distribution must be considered. The spatial variation of the source emittance due to die masks, wires, phosphors, etc. is all imaged onto the target.

++++++

This article was published in the Sept/Oct 2009 issue of LEDs Magazine. To read the full version of this article, please visit our magazine page, where you can download FREE electronic PDF versions of all issues of LEDs Magazine.

You can also request a print copy of LEDs Magazine (available by paid subscription) and sign up for our free weekly email newsletter.