Capitalize on Solar Pricing to Maximize Savings

Why Prices Keep Dropping

A cost-saving combination of financial incentives and still-falling solar PV prices makes solar power an increasingly affordable prospect. But is it right for you?

If you're on the fence about looking any further into a solar energy product, two new reports will give you some hard cost numbers to consider.

A pair of studies by the National Renewable Energy Laboratory (NREL) and the Lawrence Berkeley National Laboratory sheds light on the factors driving hardware prices and "soft" costs (the cost added to a product to cover business processes).

The cost of solar PV systems has dropped an average of 5-7% per year between 1998 and 2010, according to the hardware study. Price declines ramped up to 11-14% in 2010 and 2011, depending on system size.

This trend will continue in the near future, researchers believe. The average selling price for a solar module is expected to hit a low of 74 cents per watt this year (compared to $1.37 in 2011), thanks to a combination of falling hardware costs and a considerable surplus of components, such as polysilicon, wafers, cells, modules, and inverters.

That declining module cost drove the benchmarked price for a commercial rooftop system from $4.74 per watt at the end of 2010 to $3.43 in late 2011 – a 28% savings.

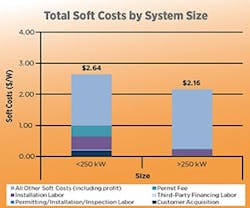

Soft costs include customer acquisition (activities such as marketing and system design); permitting, inspection, and interconnection; installation labor; and installer labor for arranging third-party financing. These processes account for roughly 17% of small commercial system price and 5% of large commercial system price as of 2010.

The Department of Energy is aiming for soft costs of no more than 44 cents per watt in commercial systems by 2020, so although prices are lower than in past years, there is still progress to be made.

Currently, soft costs add up to about 99 cents per watt for small commercial systems (roughly 17% of the total system price) and 25 cents per watt for large commercial systems (5%).

The key to reducing the cost of commercial PV should focus on the cost of installation labor, the study authors say. This is by far the biggest component of soft costs for commercial PV installations, costing 42 cents per watt for small systems and 18 cents per watt for large ones.

Both studies predict an ongoing downward trend in solar pricing, especially if "plug and play" PV systems gain viability and PV installer training and certification pick up steam.

Strides in Manufacturing Contribute to Cost Decline

The U.S. Department of Energy's (DOE) SunShot Initiative aims to reduce the installed cost of solar energy systems by roughly 75% between 2010 and 2020, according to a recent report. New technologies could make that goal a reality.

Prices have been dropping in recent years, but there is still conflicting data about PV system prices, which causes confusion and uneasiness for decision makers, says David Feldman, solar technology financial analyst with National Renewable Energy Laboratory (NREL), which authored the report with Lawrence Berkeley National Laboratory.

Manufacturers are hoping to address that confusion with innovative strides. Silicon wafers that become PV cells can take a bruising through assembly lines, as they are oxidized, annealed, purified, diffused, etched, and layered during the manufacturing process.

All those refinements render 5-10% of the costly wafers unusable. They have micro-cracks left over from incomplete wafer preparation, which causes them to break on the conveyers or during cell fabrication.

Scientists at NREL have developed an instrument that puts pressure on the wafers to find the fragile, vulnerable ones and kicks them out before the costly enhancement. NREL's Silicon Photovoltaic Wafer Screening System (SPWSS) is a cube-shaped furnace about 15 inches each side, and can be retrofitted into an assembly line.

The PV industry generated $82 billion in global revenues in 2010. Processing solar cells costs about 15 cents for each watt of potential energy, and cells make up roughly half the cost of an installed module. If innovations can eliminate the cost of the 5-10% of cells that fail before completion, potential annual savings run into the billions of dollars – which could make the goals of the SunShot Initiative a reality.