Newsworthy

Backyard Sustainability: American Hardwoods

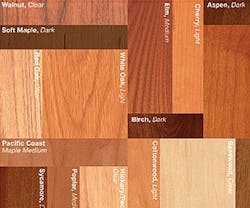

While exotic and tropical hardwoods are currently in vogue, don't overlook eco-friendly lumber options in your backyard. American hardwoods – such as oak, cherry, maple, and walnut – are an equally green option due to harvesting methods, local sourcing, and minimal processing. The Hardwood Manufacturers Association (HMA) addresses myths about hardwoods.

bolster your facility's sustainability goals. Photo courtesy of the American Hardwood Association

Myth #1: All American woods are clear-cut harvested, permanently wiping out acres of trees at a time.

HMA: Clear-cut harvesting is common to conifers, or soft woods such as pine and cedar. Because conifers cannot self-regenerate when harvested, land is either reseeded or abandoned.

Single-tree selection, on the other hand, is the preferred method for harvesting hardwoods. This practice allows trees to be selected in a cyclical pattern based on maturity. For example, an owner may have a 10-acre track of trees and only harvest half an acre once every 40 years. Within a few years of harvest, a sapling will sprout from the remaining stump.

Because of this management technique, hardwood growth is nearly double the harvest rate. According to the U.S. Forest Service, hardwood growth accelerated 119% from 1953 to 2007. Selective harvesting has created a sustainable supply of over 275 million acres across the U.S. that is continuing to increase.

Myth #2: Hardwood products are not carbon-neutral product due to the manufacturing processing.

HMA: Trees are one of the best antidotes to pollution. One ton of wood can remove 1.4 tons of carbon dioxide a year, in addition to releasing one ton of oxygen. Because processed lumber does not offgas, managing forests with harvests prevents CO2 release from decaying trees.

The amount of carbon stored during a tree's life is also significantly greater than any emissions created during manufacturing, which involves cutting, drying, and transportation. All leftover lumber is turned into usable products, such as sawdust, biomass, or mulch. Studies have shown that the energy required to produce aluminum, cement, and brick products is up to 126 times more than processing wood. Also, little energy is needed to recycle or repurpose wood.

Myth #3: Hardwood flooring products involve extensive maintenance.

HMA: Properly finished hardwood floors require minimal maintenance, such as dust mopping or light buffing, and no chemical cleaners are necessary. The nonporous surface of hardwood doesn't encourage mold and bacteria growth.

Repair work typically involves refinishing, which allows you to change the look if desired. With proper care, hardwood floors can last from 75-125 years. The original hardwood floors that Jefferson installed at Monticello can still be walked on today.

Myth #4: When pursuing LEED, American hardwoods will not qualify for a point.

HMA: The LEED MRc7 credit for certified woods currently awards one point for FSC-certified wood products. Because over 70% of American hardwood forestland is privately owned by families and small businesses, many cannot justify the cost of third-party certification. While there are a few FSC-certified American hardwood products available, this point is difficult to achieve.

However, you can still earn a LEED point for regional sourcing if the hardwood was harvested within 500 miles of your site. Working with an area mill positively affects your local economy.

Myth #5: Bamboo is more eco-friendly than hardwoods.

HMA: While bamboo is a rapidly renewable source, it is actually a grass, not a hardwood. Bamboo strips must be compressed with chemical-based glue under extreme pressure, and only 35-65% of the raw material is usable during manufacturing. Bamboo also has a shorter lifecycle compared to hardwoods – only 30-50 years. You should also consider how far bamboo and other tropical woods must travel before reaching your facility. Think of how much carbon is used to transport lumber across the ocean as opposed to a hardwood that can come from within your state. American hardwoods offer long-lasting, locally sourced products that easily bolster your facility's sustainability goals.

Where Do You Rank in the Range of Facility Manager Salary?

Information courtesy of PayScale, Inc.: www.payscale.com

Food Manufacturers Harness Solar, Fuel Cell Technology

Three U.S. food makers aim to cut the energy they draw from local utility grids by kicking off ambitious solar and electrochemical projects.

Snyder's of Hanover, the second largest snack food company in the U.S., recently began construction on a 20-acre, 16,000-panel solar farm at its Hanover, PA, headquarters. The panels will reduce carbon dioxide emissions by over 230 million pounds over 25 years. The energy created equals more than 11 million miles not driven by a medium-sized car.

In April, House Foods America, one of the country's biggest tofu manufacturers, opted to install a 215-kW photovoltaic solar array at its manufacturing plant in Garden Grove, CA. The rooftop solar electric system will prevent the release of 675,000 pounds of carbon dioxide into the atmosphere every year.

Meanwhile, Coca-Cola Refreshments USA recently announced that its Elmsford, NY, production facility can now power some of its operations with two UTC Power cells, which produce electricity, heat, and water through an electrochemical process. This prevents the release of more than 2,635 metric tons of carbon dioxide that would be produced by a non-base load utility power plant.

The projects reduce demand for local electricity by producing some of the plant's energy in-house, reducing the expensive peak energy costs associated with daytime manufacturing in a process known as load shaving. They also provide a strong cost savings for the manufacturers.

Model Energy Code to Boost Efficiency

Just days before the 2010 elections, the International Code Council voted to pursue a 30% boost in energy efficiency in new home and commercial building construction.

The new International Energy Conservation Code, which sets standards for efficient building, aims to reduce wasted energy from homes and commercial buildings, which consume nearly half of the nation's energy.

To help commercial buildings meet the 30% goal, delegates opted to increase insulation, reduce energy waste from leaky ducts, and improve hot-water distribution, among other proposals.

States and cities must now decide whether to adopt this code revision and require improved efficiency locally.

More Women Entering Commercial Real Estate, But Wage Gap Endures

More women are carving out a niche in the commercial real estate industry today than in 2005, but are still more likely to confront salary and promotion disparity, according to a new study released recently by the Commercial Real Estate Women (CREW) Network.

Commercial Real Estate: 2010 is a follow-up to the first-ever in-depth look at the status of men and women in commercial real estate, which the CREW Network conducted in 2005.

Responses from over 2,900 agents in a wide variety of specialties show that 43% of people entering the field are women, compared to 36% in 2005. The study found an increase in women with fewer than five years of experience and women with more than 20 years of experience.

The study also revealed that the wage gap is narrowing with several key findings:

- In 2010, 11% of female respondents were making $100,000 to $250,000 per year, a significant increase over 2005, when just 8% were in that category. The percentage of men in the same wage bracket decreased from 34% to 31%.

- Three times more male than female respondents are represented at the $250,000 level this year.

- Twice as many women as men earned less than $75,000 per year, as opposed to three times as many in 2005.

"We are encouraged that more women are finding opportunity in commercial real estate," says Kristin E. Blount, 2010 president of CREW Network and a vice president and partner at Colliers, Meredith, and Grew in Boston. "Compensation and advancement issues remain, but these may be a reflection of differing long term goals with respect to men and women, as reflected by our questions on this topic."

To learn more, see the study's executive summary at www.crewnetwork.org.

Thermal Comfort Is a Temperate Subject

Complaints of temperature once again topped the list of top office complaints among employees, according to Temperature Wars: Savings vs. Comfort, an IFMA survey.

Comfort directly relates to worker productivity, so facility managers strive to keep facilities comfortable for workers. A major goal of the study was to identify the nature of the complaints and what actions and improvements are being made to ensure workers are comfortable and able to concentrate on their jobs.

Federal Building Goes Green with Stimulus Help

The U.S. General Services Administration (GSA) is embarking on its first utility-scale solar electric project with help from the American Recovery and Reinvestment Act.

The 914-kW photovoltaic system, currently being installed atop the Chet Holifield Federal Building in Laguna Niguel, CA, will produce more than 1.4 million kWh every year, enough to power about 130 homes. It will save about 1.8 million pounds of carbon dioxide gas annually, the equivalent to taking 800 cars off the road.

The system will be the second largest photovoltaic installation in Orange County and is the agency's first utility-scale photovoltaic project. All of the components are manufactured in the United States, including the 3,808 silicon photovoltaic modules.

The GSA plans to use the Holifield building as a case study and reference point for future solar projects.

Loyola University Drives Biodiesel Production

The Loyola University Chicago Center for Urban Environmental Research and Policy's (CUERP) Biodiesel Program is now licensed by state and federal authorities to produce and sell its biodiesel fuel, making it the first school program in the U.S. to do so.

The biodiesel, manufactured from cafeteria waste oil, can be sold to area businesses. The first customer is The Free Enterprise System, Inc. – the company that operates the university's shuttle service between the Lake Shore and Water Tower campuses. The company can run its six Loyola buses with less fuel, eliminating the use of almost 3,000 gallons of diesel fuel each year for the shuttles due to purchasing the biodiesel.

"The growth and success of our biodiesel lab has been amazing and we will continue to expand not only our production and sales, but also our outreach to schools, small businesses, and individuals interested in biodiesel," says Zach Waickman, lab manager for the biodiesel program. "It is like running a small business that will be financially sustainable by finding unique ways to benefit the environment."

The program began in 2007 when CUERP received a $10,000 grant from the EPA to implement a new educational model on campus called Solutions to Environmental Problems. It is now a stand-alone program run by students with the help of only one biodiesel lab manager. To date, the lab has produced more than 1,500 gallons of biodiesel.

"Our work has just begun, as our biodiesel program plans to collaborate with other universities in the Chicagoland area to collect waste vegetable oil, convert it into biodiesel fuel, and then sell it to other community circulator buses and universities," says Nancy Tuchan, vice provost and former director of CUERP. "I'm so proud of what our students have accomplished thus far, along with their passion for finding solutions that protect the environment and ultimately will make the Loyola community a greener place to live, work, and study."

Seattle University Bans Selling Bottled Water

Seattle University (SU) is now the sixth university to stop selling plastic bottled water on its campus by participating in the "Think Outside the Bottle" campaign. Developed by Corporate Accountability International, the initiative aims to "restore faith in public tap water" by encouraging businesses to forgo bottled water in favor of tap.

The "Think Outside the Bottle" campaign emphasizes the environmental benefits of returning to tap water, which include:

- Public water systems are regulated and accountable to the public for water source and quality, whereas many bottlers are not.

- Tap water costs thousands of times less than bottled water for the same product. For example, Seattle tap water costs half a penny per gallon compared to $9.60 a gallon for bottled water brands.

- Only 2 in 10 plastic bottles are recycled, creating waste that is not biodegradable.

- Bottled water increases corporate control of local water resources.

- Significant levels of fossil fuel are needed to create and transport plastic water bottles – almost 2,000 times more energy than to process tap water. Plastic bottling uses approximately 54 million barrels of oil annually.

SU eliminated bottled water from vending machines, concession stands, and cafeterias. In response, bottle fillers were installed at drinking fountains and steel water bottles are sold at a discount. The switch has been positively received at SU and supports the university's goals of reducing its greenhouse gas emissions. It also reinforces its stance that access to water is a human right and not a commodity to be sold for profit.

50% Energy Savings in Hospitals a Healthy Possibility

A new report by the U.S. Department of Energy (DOE) and its National Renewable Energy Laboratory (NREL) demonstrates how to achieve 50% energy savings in large hospitals. Energy-reducing measures achieved 50-60% savings across eight climate zones and between baseline and low-energy models.

The study used a model hospital with a 527,000-square-foot footprint, seven stories, an attached medical office building, steel-frame construction, and baseline HVAC equipment. Each model was then adjusted to a specific climate zone. Energy savings were based on ASHRAE Standard 90.1-2004 minimums.

All energy design measures identified were derived from "off-the-shelf" technologies that were available from multiple sources, which include:

- Reduced lighting power densities

- Daylighting and occupancy sensors in applicable zones

- More insulative envelope (opaque exterior and fenestration)

- Overhangs on south-facing fenestrations

- A multi-zone dedicated outdoor air system

- High-efficiency chillers, boilers, and water heaters

- Demand controlled ventilation

- More efficient water-to-air pumps

- Reduced infiltration through tighter envelope construction

- Integration of subsystems to achieve whole-building performance

The DOE-NREL report identified over 30 recommendations, all of which were achieved using integrated building design.

Integrated design demonstrates how energy savings in one area affects another. For example, a reduction in installed lighting power density (LPD) can allow for a smaller HVAC system. Examining the relationships among a hospital's subsystems resulted in proactive designs to minimize energy consumption and was crucial to reaching the report's 50% savings goal.