Acronyms, such as GPS, TPO, MB, EPDM, IR, UV, VOC, NRCA, ASHRAE, RCI, FM, UL, etc., either enrich or confuse the roofing environment. Just when you thought you had things under control, someone uses “albedo,” “emittance,” “green,” “vegetated,” “cool,” “carbon footprint,” “megapixels,” “flash drives,” or some other term that tends to make you uncomfortable. Tools like cell phones, Bluetooth, Google®, text messages, etc. are ubiquitous, but they only save time if we’re willing to spend time trying to master them in the first place.

Just a few decades ago, thermal imaging of roofs (and of buildings in general) was introduced as a powerful weapon in detecting heat loss or gain in roof systems. Handheld infrared cameras were the beneficiaries of “sniper-scope” technology that could detect the enemy in the dark from the heat emitted from their bodies or vehicles.

Early infrared roof survey devices were heavy and cumbersome, required working at night, and were ineffective if the roof surface was wet. Today’s generation of devices are lighter in weight (if not in cost), but still require a difference in surface temperatures and a good measure of judgment to reliably identify where water is trapped. Thermal anomalies still require site visits and possibly also test cuts during daylight hours to judge if the “hot-spot” was actually due to wet insulation and, if so, to gather some information about how much water is actually trapped. There still isn’t an agreed-upon criteria regarding how wet is wet. No matter how high tech the equipment, under-deck heaters, roof patches, and changes in deck type, insulation type and thickness, or interior use can still mislead an inexperienced thermographer.

Ironically, thermal (and other instrumented) roof surveys are often less effective today because many roofs now use cellular foams (e.g. polyisocyanurate or polystyrene insulations) that usually, unlike their facer sheets, do not readily take on water like wood fiber, perlite, and glass-fiber insulations used to. In addition, many elastomeric roofs may be surfaced with ballast or are even vegetated, effectively hiding all but the most extreme thermal footprints. The light colors of cool roofs have high albedo (reflectivity), so they don’t absorb as much heat during daylight hours as a typical bituminous roof might, so the temperature differential between “wet” and “dry” is reduced.

Professional roof consultants are the ones most likely to take advantage of today’s survey devices, whether they use the principles of infrared, nuclear, and capacitance to indirectly identify potential areas of trapped water. Roof plans are typically generated by the consultant (if not already available) to depict locations of roof drains, direction of water flow, rooftop equipment, skylights, curbs, and flashings. Reports today often include digital photographs of important features, and may include recommendations or conclusions regarding roof condition. The U.S. Corps of Engineers uses its ROOFER program (a remarkably objective, if not time-consuming, method of establishing relative roof condition ratings, fully digitized and computerized).

In some instances, the military has conducted nighttime flyovers using either fixed-wing aircraft or helicopters to conduct the thermal imaging. The Corps has developed a method of preparing roof plans from the information gathered during the flyovers, using scaling techniques based on the known size of features on the roofs, such as HVAC units. Commercial image vendors are using satellite images with success as well.

Today, with satellite imaging, it’s possible to download aerial images with remarkable clarity directly to your desktop using infrared and visible light. Subscribers to Google Earth Pro may download fairly high-resolution photos of a known scale, allowing consultants to make roof-plan drawings of larger roof areas.

At the same time, portable global positioning system (GPS) devices and handheld computers with customized roofing software enable a roof-survey team to quickly measure, locate, and photograph all roof features of interest. This information is automatically organized and compiled so that conditions, observations, conclusions, and recommendations can be quickly communicated with back-up documentation.

Yet, with all of this survey power, there are some things that only the building owner and manager can do. One that is not done often enough is to identify what items on the roof are no longer in service. Every penetration on a roof surface is a potential leak, both of water and of heat energy. Payback on removal can be quite quick, especially for large curbed equipment. During reroofing, not having to work around and flash any unused equipment is a cost savings.

When the building owner does not wish to face the expense of removing superfluous equipment, polyurethane foam can be sprayed over the units and associated ductwork, serving as an air barrier and as thermal insulation, reducing heat loss dramatically.

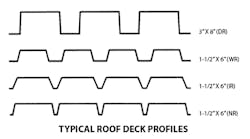

If equipment removal cannot be readily or practically performed as part of routine maintenance, it almost certainly makes sense prior to any reroofing operations. Roof-deck manufacturers and deck-trade associations (e.g. Steel Deck Institute and National Roof Deck Contractors Association) provide guidelines on how to fill in the gaps to make the deck level and remove and replace damaged decking. The profile of the existing deck needs to be established (see Fig.1) so that, when unneeded equipment is removed, you have replacement decking with the same profile on hand so it will nest with the adjacent decking. Finding replacement types A and F deck, however, can be a challenge, and special accommodations using more readily available, type B deck will be required.

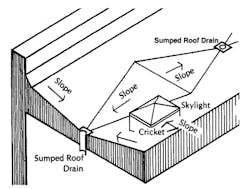

Many existing roof decks have inadequate slope. Ponding is undesirable on all roof systems. Locating puddles on a roof plan where they remain for more than 48 hours after a rainstorm may indicate where drainage needs to be addressed. (Some authorities recommend only dealing with standing water that remains after 48 hours; some exert requirements that are more stringent.) One option is to add new roof drains or to reset existing drains so water can flow freely off of the roof. Another option is to look at where the water is impeded. Saddles (see Fig. 2) can be constructed on the upstream side of curbs to deflect the water around the obstructions. Tapered roof insulation, plywood, OSB, fabricated metal diverters (on metal panel roofs), or even tapered spray-in-place foam can resolve some of these issues, at least until reroofing is done. At that time, thermal insulation will probably be needed to meet the new energy codes, and tapered materials can be easily added.

The question comes up: What do I do if existing windows or doorsills are too low to accommodate thicker insulation layers? Creating new valley lines and rows of drains is one option. Another option is to not elevate the thickness of roof insulation all the way to the wall, but to treat the first 4- to 6-foot width as a separate roof area with its own drains and install raised curbs just beyond this area that are fully elevated (so that the rest of the water is flowing away from the curbs, perhaps toward a newly created valley-line).

Some years ago, most building codes called for a minimum of a 0.25-inch-per-foot slope, tempering this somewhat for existing buildings where increasing slope would be a burden. Nowadays, the codes require positive drainage. If a roof is ponding 48 hours after rainfall has ceased, one could conclude that drainage is not positive (even if the roof intended to have a 0.25-inch roof slope). With this new definition of positive slope, installing tapered insulation needs to be sufficient to overcome slope loss from deck deflection. Crickets and saddles should kick water away from obstructions; the new valleys formed by insulation build-up require positive slope to drain as well.

What are the objectives of all this mapping and inspection?

- It’s easier to associate defects on the roof with active leaks.

- It enables development of long-range (and immediate) financial plans for roof maintenance and replacement.

- It enables corporate management to objectively compare roof conditions (i.e. using ROOFER) between all buildings in the inventory, and to prioritize repair or replacement.

- It enables comparisons of performance between differing roof systems to determine which are actually providing the lowest life-cycle costs and enable realistic estimates of roof life.

For building managers, consideration should be given to establishing an in-house roofing expert. Some of the courses from the now-defunct Roofing Industry Educational Institute are available through the National Roofing Contractors Association, including Roof Inspection, Diagnosis and Repair. The NRCA also has a maintenance manual for low-slope roofing, which was developed in cooperation with the Asphalt Roofing Manufacturers Association (ARMA) and the Single Ply Roofing Industry (SPRI). Educational programs are also available from the University of Wisconsin-Extension (e-mail [email protected] for more information) and RCI, as well as from major roofing manufacturers.

Meanwhile, if you do not have current roof plans and a program for roof inspection, maintenance and replacement, what better time to create one than now?

About the Author

Richard L. Fricklas

Richard (Dick) L. Fricklas received a Lifetime Achievement Award and fellowship from RCI in 2014 in recognition of his contributions to educating three generations of roofing professionals. A researcher, author, journalist, and educator, Fricklas retired as technical director emeritus of the Roofing Industry Educational Institute in 1996. He is co-author of The Manual of Low Slope Roofing Systems (now in its fourth edition) and taught roofing seminars at the University of Wisconsin, in addition to helping develop RCI curricula. His honors include the Outstanding Educator Award from RCI, William C. Cullen Award and Walter C. Voss Award from ASTM, the J. A. Piper Award from NRCA, and the James Q. McCawley Award from the MRCA. Dick holds honorary memberships in both ASTM and RCI Inc.