Greener than Green

The focus in the roofing business this past year has been on energy conservation, sustainability, green roofs, and recycling. In terms of “new,” not much has been introduced in the way of roofing products and systems.

Perhaps this is due to the shrinking number of manufacturers in the roofing business through mergers and acquisitions, the achievement of stable and reliable roof systems, the attainment of commodity status for TPOs, or the fact that we have optimized roof performance, and gains will be harder to come by in the future.

Recently published data reveals that there are satisfactory alternatives to reflective roof coatings, such as ballasted roof systems, cool pigmented coatings for metal roofs, and the use of vented tile systems. This is good news for individuals who do not find white roofs particularly attractive, especially when dirt and mold build up, or when coatings start to crack and peel, requiring recoating. Energy-conserving pigments also offer alternatives to white, reducing the potential for glare complaints while offering more attractive earth tones.

The jolting increase in the cost of petroleum appears to be a permanent shift – one that will challenge us for years to come. Petroleum-based built-up roofs (BURs) and modified-bitumen (MB) systems may be especially hard hit. MB has survived in Europe, even though the cost of petroleum has been extremely high for decades since it used far less bitumen than the conventional BUR system.

In a 1992 issue of RSI magazine, a table was provided of the costs of energy that were current at the time.

|

|

Gasoline/liter |

Electricity/kWh |

|

Canada |

0.499 |

0.064 |

|

Denmark |

0.957 |

0.144 |

|

Finland |

1.068 |

0.100 |

|

Japan |

0.972 |

- |

|

Netherlands |

1.104 |

- |

|

Sweden |

1.145 |

0.107 |

|

U.S. (Then) |

0.30 |

0.080 |

(For related information on the average cost of electricity in the United States, visit the Energy Information Administration website.)

Since it appears that the United States is just catching up to the rest of the world on petroleum prices, we should not expect a reversal to the good old days.

It is also evident from last month’s issue of Roofing News that we have maxed out on savings from increasing the minimum R-value of roof insulation. (ASHRAE 90.1 has recently raised the minimum R-value required for most commercial buildings to 20 from 15, with just a marginal improvement in energy savings.) We need to find and implement other ways to conserve energy.

Let’s consider some possibilities:

| Changes |

Pros |

Negatives |

Comments |

|

Increase durability |

Delay disposal |

Increased maintenance expenditures |

Upgraded systems are available |

|

Increase thermal mass |

Reduce reliance on reflective coatings and aged R-value of foams |

Increased weight |

Concrete roof decks and ballast provide thermal lag |

|

Increase slope |

Better drainage; |

May cost more to make conversion |

Sloped roofs require less maintenance |

|

Increase drainage |

Tapered insulation available |

Best when reroofing |

Able to redirect water to drains |

Estimating the longevity of current roofing systems is very complex due to the number of variables. In 1996, members of Raleigh, NC-based RCI Inc.-The Institute of Roofing, Waterproofing, & Building Envelope Professionals were polled on their estimates of the effect of certain variables on membrane roof life. The following results were reported in the September 1997 issue of RCI’s Interface magazine.

Using a 3-ply BUR applied directly over Isoboard, respondents estimated an average roof life of 12.1 years.

Effects of the listed changes on roof life follow:

- Add flood coat and gravel surfacing – 1.4 years of extended life (equaling an expected life of 13.5 years).

- Add fourth ply with gravel – 6.5 years of extended life (equaling an expected life of 18.6 years).

- Use coal-tar glass felt pitch/gravel – 6.8 years of extended life (equaling an expected life of 18.9 years).

- Use BUR/protected membrane roof (PMR) – 8.1 years of extended life (equaling an expected life of 20.2 years).

- Use coal-tar with organic felts/gravel – 8.9 years of extended life (equaling an expected life of 21.0 years).

Expected life for modified-bitumen roof systems (MBs):

- Standard Glass Base, APP cap - 10 years.

- Standard Base, SBS cap - 10.9 years.

- 2-ply glass BUR, SBS cap - 13.7 years.

- SBS base/SBS cap - 14.6 years.

- Any MB in PMR configuration - 15.4 years.

Expected life for elastomerics and thermoplastics:

- Black EPDM/45 mil - 10.4 years.

- 60 mil reinforced mechanically attached/taped laps - 14.2 years.

- PMR configuration - 19 years.

- PVC membranes - 12.5 years.

- (TPO was not available in 1992.)

While these are undocumented opinions from a limited survey, certain opportunities are revealed.

With single-ply systems:

- There is reduced labor.

- More of the membrane is produced in the factory.

- There is a greater potential for recycling at end of the membrane’s life.

- Buyers can select from a choice of highly reflective colors.

- Users may not need to recoat.

- You can expect a lower carbon footprint since they have lower petroleum content.

With PMR systems:

- The membrane is protected against hail, mechanical abuse, and UV exposure.

- Both the ballast/pavers and extruded polystyrene thermal insulation may be reused at end of membrane life.

Use of overlay boards (i.e., gypsum boards):

- Increases thermal mass and resistance to hail, wind (depending upon attachment method), fire, and mold.

With vegetated roofs:

- All the additional components (vegetation, drainage materials, etc.) make potential savings ambiguous at this time.

Converting to Steep-Sloped Roofs

In the Construction Engineering Research Laboratory (CERL) Report M-85/05, dated December 1984, the advantages of converting low-slope roof systems to steep roofs were discussed. While life-cycle advantages are present, aesthetics are also improved and roofing problems are greatly reduced. Cost estimates were also provided in the summary, as follows:

Converting flat-roofed buildings to sloped roofs proved to be a viable alternative to reroofing. This method was cost effective when considering the life-cycle costs, particularly for smaller buildings. Sloped-roof conversions are being done in most areas of the country, regardless of geographic area or climatic region. Finally, this type of conversion often had the benefit of enhancing the appearance of the buildings and solving other problems associated with flat-roofed buildings.

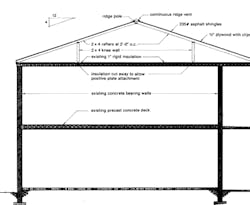

For many Bauhaus-style buildings (i.e. box-like buildings with very flat roofs), converting to sloped roofs suitable for architectural metal, shingles, or tile has the potential to greatly increase life while improving appearance, providing a vented attic, and reducing roof maintenance to a negligible level (see Fig 1.).

In the same September 1997 issue of Interface magazine mentioned earlier, RCI experts were asked to estimate the reduction in roof life if the roof system drained poorly and suffered from areas of ponded water. The estimated reduction in roof life ranged from 1 to 3 years or 3 to 5 years for most systems. (Only coal-tar pitch suffered less – a 0- to 1-year reduction in life.) That might not sound like much, but if roof life is typically 15 years, then a 3-year improvement equals 20-percent longer life.

The effect of maintenance on service life was similar, with a hybrid BUR/SBS cap sheet system benefitting the most, with life projected to increase by 1 to 5 years with proper maintenance.

With photovoltaics coming into their own, a steeply sloped roof enhances performance through improved solar orientation of the panels. Elevation of the panels above the shingles/tiles may be easier to accomplish on a sloped platform, and the attic space provided by sloped roof systems may help reduce the effect of increased heat load generated by the panels themselves. Access to the electrical components of the panels may also be facilitated by placement in the attic space.

One last thought: On a recent trip to Southern California, I stopped at an outlet mall in Pismo Beach; air temperature was in excess of 105 degrees F. As we approached one of the upscale department stores, we noticed that all four doors to the store were wide open. You could feel the air-conditioned air pouring out of the building from 30 paces away. Increased R-value in the roof won’t help much if we forget the basics.