Explore HVAC Chilled Beam Systems

"It's a fan coil without a fan," says David Callan, senior vice president, director of sustainable design and high-performance building technology, Syska Hennessy Group, Chicago. "It has chilled water piped to it, and it provides convective cooling. You get underfloor air distribution benefits in a ceiling-based system."

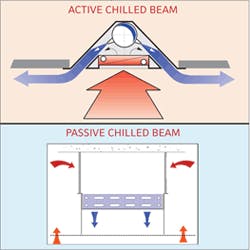

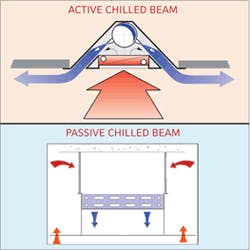

Chilled beam systems are available in three variations: passive, active and integrated/multi-service beams. The difference between passive and active beams revolves around the way airflow and fresh air are brought into the space. Integrated/multi-service beams are chilled beam systems that include lighting, speakers, sprinkler openings, cable pathways, etc. "We've not yet been able to incorporate them into a U.S. project, but I've seen it done in the U.K. It essentially becomes a very customized ceiling element," says Rob Bolin, senior vice president, Syska Hennessy Group, Chicago.

Related: Don’t Let Sick Building Syndrome Reduce Productivity

How it works:

With goals of eliminating excessive fan energy and reliance on reheat, a chilled beam acts as a radiator chilled by recirculated water. Warm air rises and is cooled by the chilled beam; once it's cooled, the air falls back to the floor, where the cycle starts over. Passive chilled beams require ventilation air to be delivered by a separate air-handling system; in an active beam, the ventilation air is delivered to the beam by a central air-handling system via ductwork.

"It's essentially taking an induction unit, turning it upside down, and having it ceiling mounted," says Bolin. "The ventilation air is passed through a duct that's part of the chilled beam and induces room air up over the cooling coil, mixes with the primary ventilation air, and delivers it through the linear diffusers."

Benefits:

- Because they have no moving parts, chilled beam systems are quieter than VAV systems and are easy to maintain.

- Floor-to-floor height can be reduced and space can be maximized because chilled beams don't need equipment/mechanical rooms or large ductwork.

- Fan use is minimized, which saves energy. As Greg Allen, sustainable design strategist at HOK, Toronto, points out, it's more efficient to pump water than to blow air: "To move the same quantity of cooling by water than by air transport is about a 10:1 ratio."

- "You have the potential for better thermal comfort because these systems have a better air-distribution pattern," says Callan.

Drawbacks:

- Chilled beam systems may cost up to 15-percent more than conventional VAV systems and are manufactured primarily overseas; they can be hard to obtain, contributing to high costs.

- Many MEP engineers aren't very familiar with this technology.

- Condensation can occur, so conditions must be kept within a certain range. "You can't let surface temperature of the chilled beams get too cold because condensation will form. There's a limit to how much cooling can be accomplished by a chilled beam. You can't just drive the temperature lower," says Erik Ring, director of MEP services at Irvine, CA-based LPA Inc.

- Positioning chilled beams isn't easy. There needs to be adequate space between the top of the passive beam and the bottom of the structure to make sure warm air can rise, turn, and go past the heat exchanger's cooling fins. Passive beams shouldn't be located above work areas due to drafts. They should also be kept away from copy machines, printers, etc.—the warm air from these machines offsets the cool air from the beam.

Where it works:

"These systems are better for projects where your air-conditioning system is sized based on heating and cooling loads rather than ventilation," says Callan. "If the ventilation system has to be so big that it could very easily handle heating and cooling simultaneously—meaning that you're not going to be able to reduce the size of the ventilation system - then it really doesn't pay."

Buildings with heat gain from equipment, solar radiation, etc. are also candidates. "We're also starting to look at this technology in healthcare facilities," says Bolin. He points out that you need to be mindful of restrictions in certain jurisdictions if you're looking at chilled beams for healthcare.

In spaces where thermal comfort is important, chilled beam systems can work well. "If you've just got people walking through a lobby, then you probably don't need to spend the money," says Callan.

As you consider systems like these that work best for small heating/cooling demands, things like envelope design and building orientation are important, says Richard Williams, VP, architecture and sustainability, at HOK, Toronto. "There's a much greater drive toward looking at higher-performance building envelopes and the opportunities they create for alternative systems that ordinarily wouldn't have the capacity, or would be too expensive in a run-of-the-mill building."

This article was first written in 2008 and remains accurate as of 2018.