Design, Spec, and Go?

While other important factors come into play during the product selection process, Buildings readers say they want to make the final decision on which products are used in new construction, modernization, and renovation projects.

Sixty-one percent of 2004 Buildings Reader Profile respondents say that while they allow consultants (such as architects and engineers) to recommend products during the selection process in new construction, in the end, it's the facilities team that makes the final decision. Another 26.1 percent report that they do their own specifying without any outside recommendations for new construction projects. Conversely, 36.5 percent of respondents say that they always do their own specifying for modernization projects on existing buildings - without any outside recommendations.Of course, it all depends on the product, says Joseph A. Boni, facility manager for the Chicago Symphony Orchestra.

"Product selection by a consultant or me depends on my product-specific knowledge, what research I have done prior to engaging with the consultant, and my familiarity (i.e. past experiences) with a product," he says. "I have been known to 'push back' on architects and engineers with regard to their specs, and request something different or more modern. I have also accepted their spec without any hesitation. It all depends on the product."

Do Consultants Know All?

Often, a consultant will suggest the best possible product for the spec; but not always, says Elizabeth Muskat, a licensed architect and the New York City-based vice president and regional director of operations for Grubb & Ellis Management Services' Northeast region.

"I've worked on projects where the architect specifies a whole bunch of stuff, and it's a bunch of bunk," she says. "I find that architects like to work with people who are easy to work with, like all of us. The nicer the rep, the better they do in the specs."

This, Muskat says, can sometimes lead to specification and installation of products that aren't necessarily best for the particular project.

"Sometimes, I'm not sure there is a real evaluation of what works for the clients," she says. Muskat adds that it's crucial for facilities professionals to stay active in the product selection process, even when working with an experienced consultant. Facilities managers need to stress a true evaluation of each product under consideration, she says.

Al San Filippo, senior vice president for development and construction at Brookfield Properties in New York City, notes that outside consultants can be a valuable resource in providing guidance toward a solid product specification. But, he says, it's always important to do your homework.

"As long as we can substantiate our concerns, [the consultants] listen. You have to go to the consultants with facts," he says.

The Project Dictates the Spec

Choosing the right product for the job is crucial, and often it's those who do the ongoing maintenance who know best what will work in a space and deliver a true long-term return on investment.

"We look at the performance criteria," San Filippo says. "We look to see if it will yield a lower operating cost, and then compare that to the term of the lease or the life of the equipment."

Muskat uses financial institutions as a prime example of this approach. "Within their operations, there are vastly different scopes," she says. "The main or regional sites generally have a lease of 10 to 20 years, depending on the city. When you talk about fitting out that kind of space, you want something that isn't trendy and that will last past the 10-year mark." Then there's branch banking, or what Muskat refers to as "popcorn banks" that crop up in the suburbs. "Typically, those leases are for 5 years," she notes. "Most of the time the market is not stagnant for 5 years, so an institution frequently will close one branch and re-open elsewhere during that time span. To invest in a durable product for that site, you don't need to spend that kind of long-term wear-and-tear dollar. The same thing probably holds true for other 'fire' industries, such as insurance and real estate - industries where you have corporate and regional offices, and also branch offices."

It's crucial to develop an evaluation process that works and that allows you to sort through the vast array of products on the markets, Muskat says."We evaluate multiple products," she notes, adding that product decisions at Grubb & Ellis don't necessarily always come down to price.

"When you talk about people who cut a deal for 200,000 square feet, that's a big number; you don't want the wrong product in there," she points out. "If it costs you 30-percent more to put the right product in, you'll realize your investment when you don't have to tear it out a couple of years later because it didn't perform."

Within Brookfield's 47 million square feet of office space in the United States and Toronto, fitting out of spaces with interior products - including ceiling systems and flooring - is left up to tenants and their architects. The firm specifies, purchases, and installs only products relating to infrastructure, such as lighting, HVAC, windows, curtainwall, and life safety systems - the backbone of the building. For any of these categories, demonstrable, ongoing performance is what puts vendors on the specs, San Filippo says.

"We know what works for us and what keeps costs down," he says. "Our goal for our tenants is to keep ongoing operating expenses down."Putting Forth Preferences

Some facilities professionals opt to provide outside consultants with definitive guidelines that spell out product preferences by developing preferred product lists or specification standards.

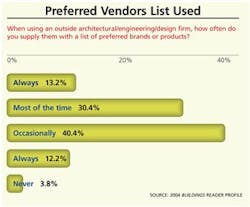

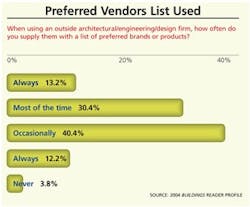

In the 2004 Buildings Reader Profile, 13.2 percent of respondents say they always work to supply architectural, engineering, and design firms with a list of preferred brands or product types; 30.4 percent say they do this most of the time; and 40.4 percent do it at least occasionally.

Sixty-one percent of 2004 Buildings Reader Profile respondents say that while they allow consultants (such as architects and engineers) to recommend products during the selection process in new construction, in the end, it's the facilities team that makes the final decision. Another 26.1 percent report that they do their own specifying without any outside recommendations for new construction projects. Conversely, 36.5 percent of respondents say that they always do their own specifying for modernization projects on existing buildings - without any outside recommendations.Of course, it all depends on the product, says Joseph A. Boni, facility manager for the Chicago Symphony Orchestra.

"Product selection by a consultant or me depends on my product-specific knowledge, what research I have done prior to engaging with the consultant, and my familiarity (i.e. past experiences) with a product," he says. "I have been known to 'push back' on architects and engineers with regard to their specs, and request something different or more modern. I have also accepted their spec without any hesitation. It all depends on the product."

Do Consultants Know All?

Often, a consultant will suggest the best possible product for the spec; but not always, says Elizabeth Muskat, a licensed architect and the New York City-based vice president and regional director of operations for Grubb & Ellis Management Services' Northeast region.

"I've worked on projects where the architect specifies a whole bunch of stuff, and it's a bunch of bunk," she says. "I find that architects like to work with people who are easy to work with, like all of us. The nicer the rep, the better they do in the specs."

This, Muskat says, can sometimes lead to specification and installation of products that aren't necessarily best for the particular project.

"Sometimes, I'm not sure there is a real evaluation of what works for the clients," she says. Muskat adds that it's crucial for facilities professionals to stay active in the product selection process, even when working with an experienced consultant. Facilities managers need to stress a true evaluation of each product under consideration, she says.

Al San Filippo, senior vice president for development and construction at Brookfield Properties in New York City, notes that outside consultants can be a valuable resource in providing guidance toward a solid product specification. But, he says, it's always important to do your homework.

"As long as we can substantiate our concerns, [the consultants] listen. You have to go to the consultants with facts," he says.

The Project Dictates the Spec

Choosing the right product for the job is crucial, and often it's those who do the ongoing maintenance who know best what will work in a space and deliver a true long-term return on investment.

"We look at the performance criteria," San Filippo says. "We look to see if it will yield a lower operating cost, and then compare that to the term of the lease or the life of the equipment."

Muskat uses financial institutions as a prime example of this approach. "Within their operations, there are vastly different scopes," she says. "The main or regional sites generally have a lease of 10 to 20 years, depending on the city. When you talk about fitting out that kind of space, you want something that isn't trendy and that will last past the 10-year mark." Then there's branch banking, or what Muskat refers to as "popcorn banks" that crop up in the suburbs. "Typically, those leases are for 5 years," she notes. "Most of the time the market is not stagnant for 5 years, so an institution frequently will close one branch and re-open elsewhere during that time span. To invest in a durable product for that site, you don't need to spend that kind of long-term wear-and-tear dollar. The same thing probably holds true for other 'fire' industries, such as insurance and real estate - industries where you have corporate and regional offices, and also branch offices."

It's crucial to develop an evaluation process that works and that allows you to sort through the vast array of products on the markets, Muskat says."We evaluate multiple products," she notes, adding that product decisions at Grubb & Ellis don't necessarily always come down to price.

"When you talk about people who cut a deal for 200,000 square feet, that's a big number; you don't want the wrong product in there," she points out. "If it costs you 30-percent more to put the right product in, you'll realize your investment when you don't have to tear it out a couple of years later because it didn't perform."

Within Brookfield's 47 million square feet of office space in the United States and Toronto, fitting out of spaces with interior products - including ceiling systems and flooring - is left up to tenants and their architects. The firm specifies, purchases, and installs only products relating to infrastructure, such as lighting, HVAC, windows, curtainwall, and life safety systems - the backbone of the building. For any of these categories, demonstrable, ongoing performance is what puts vendors on the specs, San Filippo says.

"We know what works for us and what keeps costs down," he says. "Our goal for our tenants is to keep ongoing operating expenses down."Putting Forth Preferences

Some facilities professionals opt to provide outside consultants with definitive guidelines that spell out product preferences by developing preferred product lists or specification standards.

In the 2004 Buildings Reader Profile, 13.2 percent of respondents say they always work to supply architectural, engineering, and design firms with a list of preferred brands or product types; 30.4 percent say they do this most of the time; and 40.4 percent do it at least occasionally.

At Iowa State University (ISU) in Ames, IA, the facilities department works with outside consultants on large capital projects, but other projects are done in-house with the university's own professional staff, says Chris Ahoy, associate vice president of facilities for the university's Facilities Planning and Management department. When working with consultants, university officials stay active in the product selection process, Ahoy notes.

"They give us various options to choose from, and we have a design manual that stipulates what is required for specific areas," he says. "The design manual provides them with general guidelines as to what safety, quality, durability, and aesthetic requirements are needed. It also provides a performance specification type. From our experience, we have found out what works for us and what does not work."

According to the 2004 Reader Profile, Buildings readers rank - on a product-by-product basis - HVAC, lighting, flooring, and roofing products as the most popular product types on their preferred vendor lists.

The list that Brookfield offers to its consultants is "as generic as possible," San Filippo notes. He says the list includes what Brookfield professionals believe to be the top three brand choices for each product on a spec. A solid return on investment and overall performance are far more important than brand, he says, provided that the product selected is the "current, state-of-the art technology."

When considering preferred brands for projects in Chicago's Symphony Center and Orchestra Hall, Boni explains that the factors guiding development of that preferred vendor list can change depending on the situation. But, he notes, a few important issues play a role in any decision. These include:Original equipment manufacturer (OEM) support and warranty.Dependability of product and ease of repair; availability of spare/replacement parts. "I will buy a product if it is manufactured locally (U.S. manufacturer or [in the] Midwest region of the United States), as opposed to Europe or even California," Boni says.Cost."I am brand-loyal until the point I find a flaw in the product," he adds. "I am always looking for and researching new products out in today's market; however, I am not quick to switch brands until I am thoroughly convinced."While longtime brand loyalty works for grocery items, Muskat says she believes unwavering faith in a brand isn't always the best idea when it comes to facilities-related products. Sometimes facilities managers make the mistake of staying with a vendor too long: You need to re-evaluate your vendors every few years and stay in touch with what is entering the marketplace."Consider the fact that you've been with someone 8 or 10 years," she says. "No one should get that comfortable. It is worthwhile that every 5 years or so, no matter how much you might love a vendor, you should test the water. You need to do it. You might get a better deal from another vendor with an equal-grade product. The only benefit to being brand loyal is if you believe you are getting muscle out of volume. Are you gaining leverage by having it?"In the end, product selection - brand and preferences aside - comes down to one goal: the overall quality of the building and its ongoing operations and performance."We pride ourselves on how we operate and design our buildings," San Filippo says. "The key for us is giving our tenants the lowest operating costs, particularly in a competitive market. It all comes down to that."Robin Suttell ([email protected]), based in Cleveland, is contributing editor at Buildings magazine.

"They give us various options to choose from, and we have a design manual that stipulates what is required for specific areas," he says. "The design manual provides them with general guidelines as to what safety, quality, durability, and aesthetic requirements are needed. It also provides a performance specification type. From our experience, we have found out what works for us and what does not work."

According to the 2004 Reader Profile, Buildings readers rank - on a product-by-product basis - HVAC, lighting, flooring, and roofing products as the most popular product types on their preferred vendor lists.

The list that Brookfield offers to its consultants is "as generic as possible," San Filippo notes. He says the list includes what Brookfield professionals believe to be the top three brand choices for each product on a spec. A solid return on investment and overall performance are far more important than brand, he says, provided that the product selected is the "current, state-of-the art technology."

When considering preferred brands for projects in Chicago's Symphony Center and Orchestra Hall, Boni explains that the factors guiding development of that preferred vendor list can change depending on the situation. But, he notes, a few important issues play a role in any decision. These include:Original equipment manufacturer (OEM) support and warranty.Dependability of product and ease of repair; availability of spare/replacement parts. "I will buy a product if it is manufactured locally (U.S. manufacturer or [in the] Midwest region of the United States), as opposed to Europe or even California," Boni says.Cost."I am brand-loyal until the point I find a flaw in the product," he adds. "I am always looking for and researching new products out in today's market; however, I am not quick to switch brands until I am thoroughly convinced."While longtime brand loyalty works for grocery items, Muskat says she believes unwavering faith in a brand isn't always the best idea when it comes to facilities-related products. Sometimes facilities managers make the mistake of staying with a vendor too long: You need to re-evaluate your vendors every few years and stay in touch with what is entering the marketplace."Consider the fact that you've been with someone 8 or 10 years," she says. "No one should get that comfortable. It is worthwhile that every 5 years or so, no matter how much you might love a vendor, you should test the water. You need to do it. You might get a better deal from another vendor with an equal-grade product. The only benefit to being brand loyal is if you believe you are getting muscle out of volume. Are you gaining leverage by having it?"In the end, product selection - brand and preferences aside - comes down to one goal: the overall quality of the building and its ongoing operations and performance."We pride ourselves on how we operate and design our buildings," San Filippo says. "The key for us is giving our tenants the lowest operating costs, particularly in a competitive market. It all comes down to that."Robin Suttell ([email protected]), based in Cleveland, is contributing editor at Buildings magazine.