Is the Next Renewable Energy Source a Step Away?

The greenest flooring may soon be at FMs’ feet – literally. An inexpensive, simple method to convert steps into usable electricity is making waves at the University of Wisconsin-Madison via wood pulp.

Already a common flooring component, wood pulp contains tiny cellulose nanofibers. When these fibers are chemically treated, they produce an electrical charge whenever they come into contact with their untreated counterparts. Embedding the nanofibers in flooring materials allows them to produce enough electricity to power lights or charge batteries, and the low cost of wood pulp means that the cost of energy-generating flooring could be on par with conventional materials when the production method is commercialized.

Similar products that harness footstep energy are often costly, non-recyclable and impractical for large-scale projects, the researchers note. But floors in areas with heavy traffic, such as hallways and places like stadiums and malls, could produce significant amounts of energy.

Unlike solar and wind generation, footstep-harvesting technology doesn’t depend on weather conditions, the researchers add.

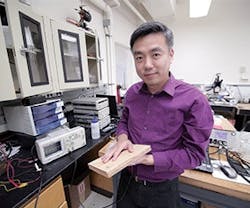

“Our initial test in our lab shows that it works for millions of cycles without a problem,” says Xudong Wang, Associate Professor of Materials Science and Engineering at the University of Wisconsin-Madison. “We haven’t converted those numbers into years of life for a floor yet, but I think with appropriate design, this technology can definitely outlast the floor itself.”

The study was published in the journal Nano Energy.