A cleaner and stronger thermoplastic may result in cheaper, greener piping and other building products.

Most commonly used in ventilation pipes and other appliances, the moldable thermoplastic polymer known as ABS has been criticized for its chemical composition, which relies on chemicals derived from non-renewable petroleum.

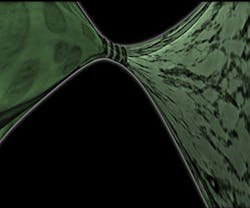

Researchers at the DOE’s Oak Ridge National Laboratory have improved the thermoplastic by replacing styrene with synthetic rubber and lignin, an organic polymer that is tougher and more economical than styrene.

Senior author and researcher Amit Naskar, along with co-inventor Chau Tran, have filed a patent application for the process to create the new material.

“We can call it a green product because 50% of its content is renewable, and technology to enable its commercial exploitation would reduce the need for petrochemicals,” Naskar says.

ORNL’s goal is to guide the new plastic to commercialization to rival older, petroleum-based alternatives.