How to Calculate Energy Conservation’s Hidden Value

You could be missing up to 31% of the hidden value of energy conservation, according to recent research.

Benefits such as decreased maintenance costs and labor, avoided capital investment, and reduced sales taxes and environmental penalties are easy to overlook, but contribute greatly to the value of your conservation projects, according to energy expert Eric Woodroof, a certified energy and carbon reduction manager.

Ready to see how much your energy conservation measures are really worth? These calculations will show you how.

Reduce Maintenance Material Costs

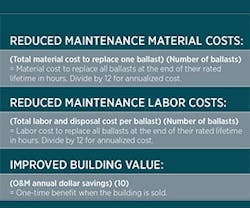

Assume that you turn off a lighting system 25% of the time, allowing the lighting ballasts and lamps to last 25% longer. You can easily assign a dollar value to the extended lifetime of both items, Woodroof says.

For example, say the ballast life is rated for 60,000 hours. If your building operates the lights for 5,000 hours per year, the lighting should be replaced in the 12th year. With 5,000 ballasts costing around $20 each, the material replacement cost at the 12th year would be $100,000.

That means the annualized material replacement cost over those 12 years would be about $8,333 a year, Woodroof explains.

However, if you can turn the lights off 25% of the time, you’re only operating them for 3,750 hours per year, which means that the ballasts should last 16 years. That reduces the annualized material replacement cost to $6,250, a full $2,083 saved just on the ballasts.

Similar calculations using this formula will help you quantify the material cost savings for the lamps, as well as motors, filters, or any other equipment that derives a longer lifetime from fewer hours of operation.

Reduced Maintenance Labor Costs

It’s similarly simple to calculate the savings on labor costs you’ll incur as a result of reduced maintenance needs, Woodroof explains.

Take the ballasts from the previous example and assume that it takes about 30 minutes to replace each one, including set-up, rewiring, and disposal of the old ballast. The labor and disposal costs for each ballast add up to $15. This means that the cost to replace all 5,000 ballasts adds up to $75,000 over the ballasts’ 12 years of operation, or $6,250 per year in annualized costs, Woodroof says.

However, if you can reduce the lighting’s hours of operation to 3,750 per year again and stretch the ballast life to 16 years, the annualized labor cost drops to $4,688, an annual savings of $1,562. Like the previous example, this formula can be applied to any other equipment affected by your energy conservation measures.

Improved Building Value

This last benefit only applies if the building is sold, but represents a considerable benefit to the building owner.

“Similar to any piece of equipment, the building’s value is partially dependent on the operations and maintenance expenses,” Woodroof explains. “For example, a hybrid car has less annual gas expenses, so it has additional market value. If a building owner is experiencing lower operations and maintenance expenses, the building will be worth more when it is sold.”

Assume that your energy conservation measures save you a total of $150,000 in O&M per year. Those savings go directly to the bottom line and increase the building value by a factor of 10. Multiply the yearly savings by 10 to find the one-time benefit from selling the building.

To learn more, read “Energy Conservation Also Yields: Capital, Operations, Recognition and Environmental Benefits,” originally published in Energy Engineering, Vol. 109 (5), 2012.