Inspection and Certification Requirements for Suspended Access Fall Protection Systems

Key Highlights

- Suspended access systems are essential for safely performing exterior maintenance on buildings three stories or taller, with system choice depending on building height and local regulations.

- All anchors used in suspended access systems must be certified by a qualified professional and recertified every 10 years, with regular inspections before each use to ensure safety.

- Proper anchor placement, spacing, and working within a 15-degree range from the secondary fall arrest anchor are crucial to prevent swing falls and ensure worker safety.

- Rope descent systems and swing stages are common suspended access methods, each with specific requirements for stabilization and connection to fall arrest systems.

- Retrofitting suspended access systems into existing buildings is feasible, but integrating them during initial construction is more cost-effective and safer for workers.

Window washing and other exterior building maintenance (EBM) tasks can be difficult to perform and pose significant safety risks for the workers performing those tasks. However, with a properly maintained system that is current on inspections and certifications, employers can be assured that their system will work as expected every single time and keep their workers safe.

What is a Suspended Access Fall Protection System?

Suspended Access Fall Protection Systems help workers safely perform exterior building maintenance (EBM) tasks. These systems are typically found on buildings three stories or taller, when routine tasks like window washing cannot be performed safely from the ground. Most buildings utilize either a rope descent system or a ground-rigged power platform (also referred to as a swing stage system), as these are both permitted for buildings under 300 feet by federal OSHA. However, Cal/OSHA only permits roof-launched systems for buildings in California 130 feet and taller. For the rest of the United States, only structures 300 feet and taller must utilize roof-launched systems. However, no matter the system selected for the building, federal OSHA 1910.27 requires all suspended access work to utilize certified anchors.

Anchor Certification Requirements

When typical fall protection anchors are used, federal OSHA 1910.140 requires anchors to be rated to withstand an ultimate load of 5,000 pounds. However, unless a fall occurs, that anchor will not be subject to much force. On the contrary, suspended access anchors are under constant tension from the workers or swing stage they are suspending. These anchors are subject to regular certification to ensure they will be able to safely suspend the worker and withstand fall forces in the event of a fall. Suspended access anchor certifications must be performed by a Qualified Person (or professional engineer) once the anchor is installed and before it is used for suspended access work. Recertification for suspended access anchors must occur once every 10 years.

First, the anchor must be pull-tested to 2,500 pounds, and the Qualified Person must verify an ultimate load of 5,000 pounds. Ample anchorages must be installed so there is a certified anchor dedicated for the primary connection of the suspension equipment and a secondary fall arrest anchorage for the worker. If the primary system fails, the secondary system can arrest the worker and prevent fatality.

Workers cannot work more than 15 degrees away from their secondary fall arrest anchor. Not only would this violate the manufacturer’s instructions for the anchor and fall arrestor, but it is an unsafe practice for workers at height. Working too far from an anchor point can cause “swing fall” during fall arrest and increase the chance of injury. Additionally, suspended access anchors cannot be spaced more than 12 feet apart.

Anchor Inspection Requirements

Like all other pieces of fall protection equipment, suspended access anchors must be inspected before each use. Workers should visually inspect the anchor to look for damage or corrosion and ensure the anchor is solidly installed. If any concerns arise or issues are found, workers should alert their organization’s Competent Person immediately so the anchor can be repaired or replaced.

Suspended access anchors are also subject to the annual fall protection equipment inspections required by OSHA. Every organization’s Competent Person must inspect each piece of fall protection equipment annually and maintain records of annual inspections.

Rope Descent Systems

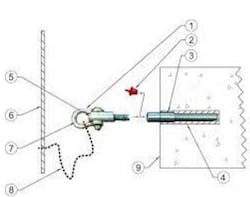

A rope descent system (RDS) typically suspends a worker by connecting a cable from a certified anchor to a bosun’s chair where the worker sits and performs their job. The worker must don a fall protection harness with a fall arrester connecting their dorsal d-ring to their anchorage. This secondary connection provides a system that will catch the worker if they fall off their bosun’s chair or if the primary line fails. If building parapets are not load-rated or have structure that the primary or secondary lines will damage, davit arms can be used to elevate anchor points and protect property (see photo at right). As workers move around the building, they will have to return to the rooftop each time to connect to the next set of primary and secondary anchors that will keep them safe.

According to federal OSHA, RDS are permitted on buildings up to 300 feet. However, buildings over 130 feet must provide RDS users with at-work stabilization methods, like suction cups, to keep them secured to the building during window washing.

Ground-Rigged Power Platforms (Swing Stages)

Swing stages are similar to rope descent systems, but instead of lowering each individual worker, they utilize a large platform that all workers share. These systems will require two dedicated davit arms that will connect to a swing stage on the ground level. The swing stage is then raised and lowered to perform maintenance. As the swing stage moves around the building, it will have to return to the ground to be moved and connected to the next set of davit arms.

Also similar to RDS, workers on a swing stage must also be connected to a fall arrestor in case they fall off the swing stage or the swing stage fails. Under 130 feet, swing stage operators are permitted to use angulated-roping techniques to keep the swing stage secured to the building. However, swing stage systems from 130-300 feet must utilize intermittent stabilization anchors (ISAs) to secure the swing stage to the building (see graphic at left). ISAs connect the swing stage to pre-determined anchor receptacles located throughout the height of the building. As the swing stage is raised up, workers must disconnect and then reconnect to the next set of ISA receptacles.

Are Suspended Access Systems Required?

Oddly enough, while federal OSHA has restrictions for these systems above certain heights, there is no clear mandate for EBM systems outside of California to be integrated with the initial construction of the building. Industry consensus suggests that buildings three stories and taller should have suspended access systems integrated into their rooftops. Furthermore, suspended access systems are typically less expensive to install during initial construction since access to the roof structure is required. However, since RDS and swing stage systems simply rely on anchorage arrays, they can be simply retrofitted into existing structures.

Suspended access systems allow workers to safely perform necessary building maintenance. It is important to protect the workers who work to protect and maintain our buildings. Buildings can be repaired or replaced, but people cannot. Prioritize worker safety always and provide workers with all the training and resources required to keep them safe. Together, we can prevent falls and save lives.

About the Author

Philip Jacklin

Philip Jacklin is Continuing Education Program Manager for Diversified Fall Protection. He is an AIA continuing ed provider, QSSP certified, OSHA-30 trained, and has been a partner to the fall protection industry since 2018. Philip has a background in worker advocacy, team leadership, and fostering camaraderie among peers. He enjoys playing music, writing, and spending time in the sunshine with his family in Virginia Beach, Virginia.