New Flooring Installation Systems Bring Advantages

The conventional bucket and adhesive approach to flooring installation might kick the bucket. New systems and technologies have floored the industry, touting benefits that traditional methods lack.

“To meet the demands of the marketplace, there is a trend moving to alternative installation systems,” explains Lewis G. Migliore, president of LGM and Associates, a flooring consulting firm. “These technologies include backing materials, bucketless adhesives, and snap-together click systems.”

Familiarize yourself with these advances and their advantages to make the right choice for your facility.

Sustainability Spurs New Systems

Adhesives traditionally incorporate harmful solvents. Around 20 years ago, the EPA started forcing manufacturers to make water-based products, which some believed hurt performance.

“In response, we developed an acrylic polymer adhesive that is pre-applied directly to any resilient flooring product. It’s elastomeric – neither solid nor liquid,” explains Devin Schlisner, operations manager of Base King, developer of the EnviroSTIX Adhesive System. “The release liner is peeled, then the flooring is bonded.”

EnviroSTIX is comparable to the Powerbond peel-and-stick system by Tandus Flooring and the polyacrylic adhesive Free Lay used by Bentley Prince Street, Migliore says.

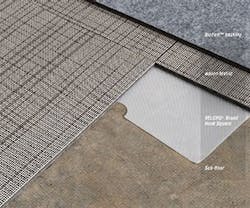

Taking a diffierent approach, Chilewich Sultan partnered with Textile Rubber & Chemical Co. and Velcro Industries to create the BioFelt tile and backing system, which “velcros” together. The entire system is then held down via silicone adhesive on the Velcro squares.

“Pressure from the design community to become greener and move away from vinyl backing systems drove us to create BioFelt, which is 82% pre- and post-consumer recycled content,” explains Joe Sultan, CEO of Chilewich Sultan. “The material is a polyester felt made from pop and water bottles.”

BioFelt is similar to TacTiles by Interface and LokDots by Shaw Industries Group, says Migliore, adding that the nature of these new technologies allows them to sidestep certain drawbacks presented by conventional systems.

Compromising Conditions Not a Concern

Aside from going green, another demand in the marketplace is for systems that resist the damaging impact of moisture and alkalinity, especially in concrete substrates, Migliore explains. “Polyacrylic adhesives are virtually unaffected by moisture,” he adds.

Between the temperature range of -20 degrees and 120 degrees C., the EnviroSTIX adhesive will remain in its elastomeric state, Schlisner says.

“The adhesive has no real shelf life,” he says. “It doesn’t dry out and lose bond like traditional adhesives. Even if you have a flood, as long as the water is cleaned up in a week or two, the flooring would be fine.”

Due to these properties, EnviroSTIX is more cost comparable to moisture remediation than bucket adhesives. It averages $2 per square foot, whereas moisture remediation can cost $3-7 and is invasive and time-consuming.

“It’s an alternative solution, and if your area is prone to moisture, that justifies the cost,” Schlisner says.PageBreak

Impact on Inhabited Space

Another driver for alternative solutions is the desire to reconfigure an area or to use the space immediately after installation. Whereas traditional options are literally stuck in place, these technologies allow flexibility.

Like click systems, BioFelt can be placed over existing floors and removed without leaving residue, presenting myriad choices for reconfiguring spaces.

“If a tile is stained or damaged, you can pop it up and replace it right away,” Sultan says, adding this makes it ideal for use in trade shows. It was used during the London Olympics this summer at a temporary facility in the Design Museum. For about a month, the BioFelt tile system covered 2,200 square feet of floor space, then was removed without a trace.

“It costs two to three times more than normal adhesives,” Sultan says. “But if you need to replace a floor quickly or remove it entirely, it’s a great solution.”

Peel-and-stick systems are permanent, but they also impact the space positively, especially if you have a time-sensitive project. Without requiring time to dry, systems like this can immediately accommodate foot traffic and furniture, Migliore says.

“We see EnviroSTIX being used a lot in healthcare settings,” Schlisner explains. “If you need to redo floors, an epoxy adhesive could take 72 hours to dry. That’s three days without an area of the hospital, which is a lot of money lost.”

Although at a premium now, these new technologies are fast becoming more common.

“We’re going down a path where adhesives out of a bucket are going to be used less and less,” Migliore says. “People need to know which new system works for their application and how it affects operations.”

Chris Curtland [email protected] is assistant editor of BUILDINGS.