Popular in Europe since the 1970s, chilled beam cooling is fairly new on U.S. shores, but is making headway in the market thanks to the booming push for efficiency. Relying on a continuous loop of water to keep rooms at a comfortable temperature, the systems cost around $24 per square foot, depending on the nuances of each individual design.

What’s the Difference?

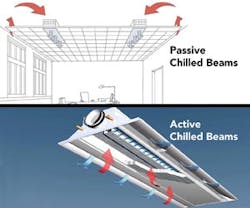

Chilled beams come in two basic styles. Passive systems use natural convection, relying on air rising as it warms and sinking as it cools. Warm air moves upward toward the chilled beam system, which includes a coil filled with cold water. (The technology can be used for heating, but this practice is less common.) The now-cooled air sinks down to where occupants can feel it, and the warmer air it displaces moves upward to be cooled. These systems are typically used to reduce an existing load or to balance out extra heat in a building with daylighting.

"The areas where passive beams might be better than an active beam would be in hallways or a space that's multi-story like an atrium," says Ken Loudermilk, vice president of technology and development at Trox USA, the first company to bring chilled beams to the U.S. "If you have a raised access floor system that you could use to pressurize and put the air in, passive beams would be a better solution."

Instead of relying fully on natural air movement, an active system forces the air through ducts and over the coil for cooling and circulation.

Some manufacturers can also engineer custom solutions by tying other ceiling-mounted services – including lighting, sprinklers, speakers, and IT cabling – into one bundle with either type of beam, a configuration commonly referred to as multi-service beams or integrated service beams, Loudermilk adds.

You may still need a chiller and fan with either system to keep the water at the optimal temperature, but the chilled beam system will take over some of the fan’s work and reduce its cost, says Michael O’Loughlin, director of business development and chilled beam product manager at manufacturer Semco HVAC.

"The biggest energy hog is the fan horsepower, the energy required to run the air handler," O’Loughlin says. "If we were to build a traditional VAV building next to a building with chilled beams, I would expect to see 50-70% less air moving to the air handler, which means 50-70% less horsepower on the fans."

Chilled Beam Candidates

The 20-year life cycle and low maintenance needs (you’ll clean the coils and surfaces every 3-5 years) lend chilled beams appeal, but not every application or climate is a good fit. High-moisture buildings would not benefit, because condensation can quickly become a problem if the coils aren’t kept dry. The beams should be insulated and humidity must be well-controlled even in milder, drier climates.

High ceilings present another challenge – even with an active chilled beam system, effective cooling still depends somewhat on convection. In a building with a high ceiling, the cooled air can warm up and rise toward the beams again before it gets down to the area it should be cooling.

Places with high or widely varying heat loads, such as data centers, "have so much heat coming out that we’re limited by how much beam we can fit in," O’Loughlin says. Conference areas, meeting rooms, and classrooms, which have high ventilation needs, would also not reap the full benefits, and spaces with open doors have an increased risk of heat and humidity from the outside infiltrating the space, according to the Chilled Beam Application Guidebook, a publication of the Federation of European Heating and Air-Conditioning Associations.

Facilities considering a long-lasting geothermal system for temperature control can connect the chilled beam loop to a geothermal source for an ultra-efficient energy solution, especially if the geosystem is providing adequately cooled water without much help from a chiller, says Rob Bolin, director of high performance building solutions at Syska Hennessy Group.

"You still have a chiller or heat pump, and there’s energy associated with that," Bolin says. "But if you have a good temperature coming out of the ground, it will potentially save you a lot of energy."

Janelle Penny ([email protected]) is associate editor of BUILDINGS.

About the Author

Janelle Penny

Editor-in-Chief at BUILDINGS

Janelle Penny has been with BUILDINGS since 2010. She is a two-time FOLIO: Eddie award winner who aims to deliver practical, actionable content for building owners and facilities professionals.