Today’s high-density computer rooms and data centers demand a new level of cooling that far surpasses the needs of the old low-density days. Computational fluid dynamics (CFD) modeling can help identify hot spots before they have a chance to cause equipment failure, saving time, money, and headaches.

You probably already have enough electrical and mechanical capacity to avoid exceeding the total cooling load, but thermal issues are still a danger if your computer room air conditioning (CRAC) units aren’t distributing air to the right places.

"It’s air that’s not being utilized appropriately," says Robert Kennedy, director of operations at Bruns-Pak of Edison, NJ. "If air is being distributed to where it needs to be, you can cut back on the CRAC units."

How It Works

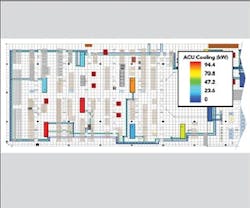

The CFD model first lays out the basic infrastructure of your computer room, including the underfloor and floor, piping for CRAC units, cable trays, and perforated tiles. Then you’ll add power distribution units and the actual data center equipment, along with their power requirements, expressed in kW per rack.

Next, identify the hot and cold aisles. Color-coding is a huge help here – for convenience, use blue for the cool inlet side of the data racks and red for the hot exhaust side. If not all of your data racks are red to red and blue to blue, you’re not using a hot and cold aisle model, which can present a problem.

"Orientation is very important," Kennedy says. "When it’s not oriented in a hot and cold aisle model and you have a CRAC unit stuck somewhere in the middle of it, you’ll lose some of the efficiency of that CRAC unit."

Armed with a completed CFD thermal analysis, you’re now ready to analyze what’s going on inside your data center. Check out the underfloor static pressure – low values indicate areas where cooling air can leak through cable cutouts or other holes to the rack’s hot air exhaust instead of cycling through the front of the rack to cool the equipment. Likewise, underfloor temperatures will tell you where cold air is recirculating due to loss of pressure, or where CRAC units are underperforming.

Flow rates should be around 1,000 cfm; lower numbers are another indicator that air is escaping through cable cutouts into the floor.

Top of rack temperatures – the temperature for the top piece of equipment in the rack – are a vital piece of the puzzle. Because these racks can get as hot as a 7-foot tower of powered toaster ovens, according to Industrial Market Trends, keeping a close eye on temperatures is paramount. In most cases, it’s best to put switches or patch panels in the top rack because they demand less energy. Top of rack temperatures help you determine where the cold air is going – if it’s going back into your CRAC units, they won’t work as hard because they sense that the air is cool, even though the equipment that needs cold air isn’t getting it.

Pair that data with the maximum inlet temperatures to find hot spots, areas that aren’t getting cool air because it’s going to the wrong places. Maximum inlet temperatures lead you to determine areas of potential overheat, the most urgent problems. Look for trends among the areas most at risk for overheating – for example, areas where cold air short-circuits, or where cable penetrations in the floor allow cold air to leak out.

What It Means

A finished CFD model is more than just a diagram of your current problems – it tells you how to efficiently operate your data center. You may need more CRACs, or you may need to optimize how well they work together.

"Team up your CRAC units and make them work in concert with each other," Kennedy says. "That increases the efficiency of the CRAC units on the floor, which in turn increases the efficiency of your whole cooling system."

Extra perforated tiles can help cool hot spots. Move the cable tray overhead to allow better distribution under the floor. Blanking panels increase efficiency by filling unused positions in the racks, which keeps cool air from leaking through empty spaces before the IT equipment can utilize it.

Hot aisle/cold aisle containment ensures you get the most bang for your energy buck by facing the intakes toward each other, where they all draw from the same cold air, and matching up the racks’ exhausts so their hot air is sucked up into an overhead return and directly back to the CRAC units.

Janelle Penny ([email protected]) is associate editor of BUILDINGS.

About the Author

Janelle Penny

Editor-in-Chief at BUILDINGS

Janelle Penny has been with BUILDINGS since 2010. She is a two-time FOLIO: Eddie award winner who aims to deliver practical, actionable content for building owners and facilities professionals.