Insulation: Comparing EPS and XPS

With today’s design-oriented goals of sustainability and energy efficiency, the proper use of insulation is becoming more important than ever. There are many different ways to insulate a building, and there are dozens of insulation assemblies in existence. This particular article focuses on two insulation types that are popular in a variety of installations for the entire building envelope: EPS and XPS.

Expanded polystyrene (EPS) foam is a closed-cell insulation that’s manufactured by “expanding” a polystyrene polymer; the appearance is typically a white foam plastic insulation material (the likes of which can be found as merchandise packaging). Extruded polystyrene (XPS) foam is a rigid insulation that’s also formed with polystyrene polymer, but manufactured using an extrusion process, and is often manufactured with a distinctive color to identify product brand.

SEE ALSO:

While EPS and XPS are two different products, they do have some similar characteristics and fall under the same manufacturing standard: ASTM C578 Standard Specification for Rigid, Cellular Polystyrene Thermal Insulation.

This particular specification covers the different types and physical properties of cellular polystyrene intended for use as thermal insulation.

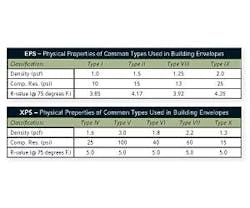

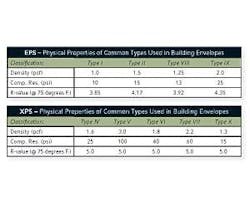

Polystyrene insulation materials that fall under ASTM C578 fall into several different classifications: Type I through Type XII (with the exception of Type III, which is no longer available). The different classifications relate directly to physical characteristics of each type – most notably, the density, compressive resistance, and R-value. The range in densities and compressive strengths allows for specific uses on different parts of a building.

Polystyrene insulation is manufactured in a variety of board sizes – usually a minimum of 1-inch thick. Tapered units are also manufactured for use in roofing assemblies where the insulation is used to create slope for positive drainage. One of the more common uses in roofing is the ballasted single-ply roof assembly, where a roof membrane is placed over the insulation and ballasted with rock, concrete pavers, or other material.

Polystyrene insulations can be used in asphalt built-up roofing systems; however, provisions must be made to protect the insulation from heat (i.e. hot bitumen or torch) and solvent-based products (i.e. adhesives). In addition, certain thermoplastic roof membranes require a separation layer between the layer of insulation and the membrane.

EPS and XPS are resistant to moisture; however, XPS is more common for below-grade waterproofing and roof systems where insulation is placed over the roof membrane (IRMA, or inverted roof membrane assembly). The IRMA concept is also utilized for insulating building walls, where polystyrene insulation is placed over a barrier membrane, with the siding or cladding system installed over the insulation layer.

The use of EPS and XPS insulation in building construction offers great flexibility, compatibility, and thermal efficiency for use at all areas of a building envelope. Picking between the two will depend on particular use; choosing the appropriate type is critical for proper insulation performance.

Steven L. McBride is president at Portland, OR-based Professional Roof Consultants Inc.

Want more insulation coverage? Sign up for our newsletters

BUILDINGS EDITOR'S UPDATE March 17,2016

For specifiers interested in insulation with recycled content, both XPS and EPS may offer solutions. Accoridng to the Department of the Interior, "Recycled plastic resin is used in some extruded and expanded polystyrene. Amoco Foam Products uses 50% recycled resin in its Amofoam®-RCY extruded polystyrene (XPS), half of which is post-consumer, according to the company... Expanded polystyrene (EPS) can also be made out of recycled polystyrene. The simplest recycling involves crumbling the old EPS into small pieces and remolding them into usable shapes. Any polystyrene can be recycled into building insulation, but because of fire retardants, old building insulation cannot usually be recycled into non-building applications." Click here for more information on environmental considerations of building insulation.