This column assumes that you know what roof systems are on your buildings, and what their performance has been over time. Realistically, your key personnel will have changed over the years, and your roofing records have probably not been kept up to date.

In the past several decades, building owners have made decisions based upon terminology such as a "20-year roof." The implication was that your roofs could last for 20 years or more, and that if the roof failed due to ordinary wear and tear, someone would fix it at no cost to the building owner. When a new roof system is contemplated, the decision will be to select the lowest-cost "20-year roof" available.

Why 20 Years?

The 20-year goal stems from the post-World War II era, when the dominant choice was a bituminous roof with asphalt or coal tar pitch as the waterproofing adhesive, pea-gravel as the surfacing to protect the bitumen from UV degradation, and felt reinforcing saturated with asphalt or pitch. For the owner, there was a 15-year choice consisting of three or four plies of felt or a 20-year system with four or five plies.

Energy, in those times, was relatively cheap, so if any thermal insulation was used, it was used mainly as a roofing substrate and might have been an inch of wood fiber, glass fiber, or perlite boards. The R-factor would have been around three or so. Flashings were not usually covered under the warranty, and since we could not retain the flood coat and gravel on a vertical slope, flashings might have consisted of mineral surfaced cap sheets or reinforced asbestos felts.

However, times changed. More and more buildings were air-conditioned by the 1950s and cellular thermal insulations such as polyurethane and polystyrene with R-values of 4 or 5 displaced insulation with lower values. By the years of the oil embargo in the early 1970s, codes were calling for R-values of 25-30 instead. At the same time, the asphalt and coal tar pitch needed for traditional bituminous roofs were in short supply, so innovation in reinforcements shifted buyers' attention to polymer-modified two- or three-ply systems. Most of the innovations were European in origin, modifying the asphalt matrix with APP (atactic polypropylene) or SBS (styrene butadiene styrene). The improvements also served to reduce costs significantly by shrinking the number of plies and replacing the flood coat with factory-applied mineral granules, reflective foils, or coatings.

Polymeric single-ply systems mounted a serious challenge to the dominance of bituminous systems, with much of the innovation coming from shorted availability of natural rubber during World War II, with such elastomeric products as neoprene, butyl, Tedlar, polyisobutylene (PIB), chlorobutyl rubber, and EPDM (ethylene propylene diene terpolymer).

Today, thermoplastics such as polyvinyl chloride (PVC), with or without scrim reinforcement, chlorinated polyethylene, Hypalon (CSPE), KEE, and now thermoplastic polyolefins (TPO) are displacing the earlier products.

Richard (Dick) L. Fricklas, received a Lifetime Achievement Award and fellowship from RCI in 2014 in recognition of his contributions to educating three generations of roofing professionals. A researcher, author, journalist, and educator, Fricklas retired as technical director emeritus of the Roofing Industry Educational Institute in 1996. He is co-author of The Manual of Low Slope Roofing Systems (now in its fourth edition) and taught roofing seminars at the University of Wisconsin, in addition to helping develop RCI curricula. His honors include the Outstanding Educator Award from RCI, William C. Cullen Award and Walter C. Voss Award from ASTM, the J. A. Piper Award from NRCA, and the James Q. McCawley Award from the MRCA. Dick holds honorary memberships in both ASTM and RCI Inc.

Are Today’s Products Proven?

Some of the above roof systems have been used with confidence going on 50 years, but others come and go. The industry relies upon accelerated tests, but these do not always translate to what Mother Nature dishes out.

PIB in particular was predicted to last at least 20 years. However, it was discovered that PIB was a great material to line the interior of a weatherometer, but under typical weather exposure, thermal loading and stress, PIB failed far short of that goal. New mechanical fasteners, low-rise urethane foam adhesives, and air barriers are still under development, so their long-term performance is still questionable as well.

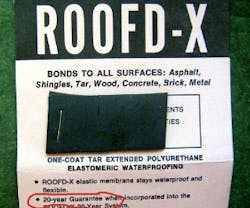

In addition, warranties offering protection for decades frequently have special requirements for maintenance, exclusions, and other factors that must be strictly adhered to in order to obtain the long life promised on the packaging. For example, many warranties exclude the increased rooftop traffic that results from adding solar panels. Optimum membrane thickness, spacing of fasteners, perimeter restraint, and periodic maintenance are still up for grabs.

Slope also makes a difference – tile, slate, and metal may qualify for long-term warranties, but it’s the positive slope of these systems that makes them viable. With shingles in particular, warranty designations may almost be considered valueless considering how the warranty is intended to apply to a particular class of building owner – for instance, a manufacturer may offer a 30-year shingle warranty only to homeowners with the understanding that the warranty will only be applicable to the original purchaser. This is because a typical homeowner will sell his building after about 10 years, and therefore warranty performance, if needed, will not have to be provided.

There are lots of factors that will influence your choices for your upcoming roofing projects, including satisfaction with what is in place and the guidance of local roofing contractors and roofing consultants. With a little luck, you will achieve that long-wanted 20-year roof system.

Is Your Roof Warranty Really Protecting You?

Read the fine print or risk voiding your coverage.

Spray Foam: When and Why?

Reasons to consider polyurethane solutions for reroofing.

Blisters: Repair or Re-Cover?

The best solution for troubled roof areas.

About the Author

Richard L. Fricklas

Richard (Dick) L. Fricklas received a Lifetime Achievement Award and fellowship from RCI in 2014 in recognition of his contributions to educating three generations of roofing professionals. A researcher, author, journalist, and educator, Fricklas retired as technical director emeritus of the Roofing Industry Educational Institute in 1996. He is co-author of The Manual of Low Slope Roofing Systems (now in its fourth edition) and taught roofing seminars at the University of Wisconsin, in addition to helping develop RCI curricula. His honors include the Outstanding Educator Award from RCI, William C. Cullen Award and Walter C. Voss Award from ASTM, the J. A. Piper Award from NRCA, and the James Q. McCawley Award from the MRCA. Dick holds honorary memberships in both ASTM and RCI Inc.