10 Steps to a Strategic Energy Plan

In this day and age, any building owner or operator who hasn't yet examined his or her energy usage, looking for more money-saving options, is hiding behind the eight ball. With energy prices on the rise and all the uncertainties of today's business climate, it is crucial that building owners take a proactive (rather than a reactive) approach to the current energy market.

Developing a strategic energy plan will help you prepare your facility for its energy future by factoring in some of the most important business decisions that will directly affect your bottom line.

Here are 10 steps that every business can take to keep its facilities competitive in today's marketplace and provide a return on investment for both your pocket and for Mother Earth.

1. Energy Forecasting

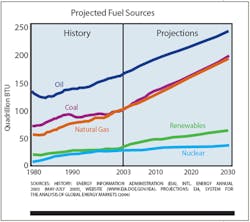

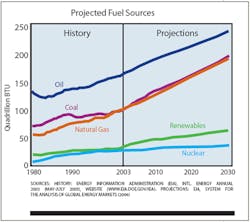

The first step in energy management is identifying where your business' energy costs are headed. A long-range (up to 20-year) energy and fuel forecast should incorporate local, regional, national, and international influences on availability, reliability, and the cost of electricity, natural gas, and fuel oil. This will provide you with the opportunity to examine your consumption on both a macro and micro level.

Forecasting on a regional level should include talking to your local utility company to better understand the make-up of your power source. Ask how they are planning to grow their fuel sources over the next few decades. Are they looking to put more sustainable power on the grid? If so, it may cost more in the early years, but may be cheaper and more energy efficient in the long run. Appreciating the fuel split ratio and its usage will help any consumer better anticipate current and future energy prices.

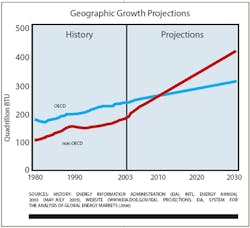

Another key to energy forecasting is looking at expenditures from an international perspective. Today, we live in a global economy where it is crucial to understand what our neighbors across the world are doing. For example, world electricity demand from 2003 to 2030 is expected to double, with 70 percent of this growth coming from non-Organization for Economic Cooperation and Development (OECD) countries, including China, India, Africa, Central and South America, and the Middle East (see graph). This future demand for energy will be a major factor in the escalation of international and, ultimately, U.S. power costs.

Fortunately, many organizations, like the U.S. Department of Energy (DOE), can make forecasting easier with annual energy reports that project international, national, and regional energy escalation and market analysis. Visit (www.eia.doe.gov) for more tips.

2. Environmental Compliance

An analysis of current, short-term, and expected future environmental compliance issues, including local, state, and federal regulations for all environmental media (air, water, solid waste, noise, etc.) is critical to formulating any facility's strategic energy plan.

Internationally, the Kyoto Protocol has been adopted by the United Nations and 165 other countries (the United States is not one of them) that have committed to reducing six greenhouse-gas emissions, including carbon dioxide, by at least 5 percent from 1990 levels between 2008 and 2012.

California is one of several states that recently adopted portions of this protocol. Under California's Assembly Bill 32, utilities, industry, and large businesses are required to go back and "clean up" existing operations by adding renewable resources to their portfolio. Electric utilities will be forced to raise the price of power to recover this investment.

You should research regional, national, and international regulations to find out how they will affect your facility and the bottom line. The EPA's Plain English Guide to The Clean Air Act walks you through present and pending environmental regulations. It can be found at (www.epa.gov/air/oaqps/peg_caa/pegcaain.html).

3. Financial Incentives

While the federal government authors most of the energy regulations existing today, state governments offer more of the financial incentives that make the edicts easier for big businesses to swallow. (Federal incentives are typically offered for research and development projects, or when a technology is first introduced to the market.) However, federal tax credits and low-interest money are available for some renewable energy projects.

You need to conduct thorough research to determine all available state, federal, and utility rebates, incentives, and tax credits, as they can save as much as 50 percent of the initial cost of employing alternative technology systems. Visit (www.dsireusa.org) for specific state and federal incentive information.

4. Energy-Conservation Measures

A list of building-specific energy-conservation measures, or areas prime for building operation and reliability improvement, can be compiled on an initial walkthrough of each facility's energy system.

Some potential areas to examine may include (but are not limited to) lighting, energy-management systems, electrical-distribution systems, building scheduling, load shedding, mini central chiller plants, thermal energy storage, utility sub-metering, the building envelope, retro-commissioning, daylighting, ventilation, waste-heat recovery, swimming pool measures, water conservation, and behavioral-modification training. An owner will typically pick the low-hanging fruit first, like lighting retrofits, which can offer easy and immediate energy and dollar savings with minimum expenditure.

5. Renewable Technologies

Every thorough energy plan will consider renewable technologies, including biomass, geothermal, hydrogen fuel cells, solar, biodiesel, and wind technologies, as potential power sources (see graph). However, determining whether any of these options is technically feasible, operationally reliable, and/or cost effective can be complicated.

Renewable technologies are site specific and utilize the natural constraints of the facility's surroundings to produce energy. Today, one common renewable technology found suitable for the average facility is a photovoltaic (PV) system, which turns solar radiation into electrical energy, typically adding high performance value to a facility because of the sun's great accessibility.

Accounting for only 5 percent of annual U.S. energy expenditures, renewable technologies are still a prisoner of their price. Their short-term economics are their sticking point, but utility or government incentives can make their long-term payback more enticing.

However, as the costs of conventional energy continue to soar, they will eventually collide with the cost of renewable technologies. At that point, the market independence that renewable technologies offer will become more of a reality for the average building. The U.S. DOE's Energy Efficiency and Renewable Energy (EERE) website (www.eere.energy.gov) can offer background information on all of the technologies available.

6. Energy Procurement

Analysis of current procurement options means evaluating the use of natural gas to see if purchasing on the open market is a good idea for your facility.

Today, many large consumers procure their own natural gas on the open market instead of going through their local gas company. Buying from an independent supplier, these businesses pay only the cost of the energy and its transportation, avoiding other charges associated with a bundled service and saving as much as 5 to 7 percent.

Electric deregulation in the United States has occurred in several states with varying levels of success. You should monitor public utility commission activities and pending legislation to determine the right choice for your facilities. Today, however, if you're the owner or manager of a large building or portfolio, you do have the choice to purchase primary vs. secondary power at a lower rate. This option should be investigated, while the benefit of lower electric rates is weighed against owning and maintaining a step-down transformer.

You also need to review the electric rate structure of your facility to verify that it is optimum for your business' needs. A variety of rate structures are available from local electric companies, including time-of-day rates, which often have more latitude.

7. Energy Source Diversification

Energy source diversification is one way that you can play the energy-management game.

As a building owner, you must understand that electric energy prices are typically structured according to a building's peak-demand usage. This means that the amount of energy used on a hot August afternoon could determine the price-per-kW consumption for a facility's peak hours of energy use year-round. (Check your local rate schedule for specifics.) Facility owners who manage their peak energy use have an opportunity to minimize their costs all year long.

Enter energy source diversification: One way to do this is to use a gas-fired chiller rather than an electric chiller during peak hours. This will shave off expensive peak-demand kW usage and typically offer significant savings to the bottom line.

Energy source diversification can also help mitigate the long-term financial operating risks associated with unexpected price increases, energy-market volatility, domestic and international politics, terrorism, supply availability, and reliability.

8. Distributed Cogeneration

Employing a cogeneration expert to perform a high-level screening analysis of distributed cogeneration options (including combustion, steam, and microturbines; reciprocating engines; and fuel cells) will help you determine which of these strategies, if any, are appropriate for your facility.

To make cogeneration a viable option, a building must have a constant electrical and waste heat thermal load. Typically, a minimum of 4,000 hours per year of operation are needed to make the economics attractive. An additional factor called "spark spread," which represents a price gap between the cost of power and natural gas, is also required.

If all these are present, distributed cogeneration can be an extremely energy-efficient alternative. A typical facility using electric utility operates at about 30- to 32-percent efficiency. When incorporating cogeneration, a plant can reach overall efficiencies in the 75- to 85-percent range.

9. Unplanned Utility Outage

Buildings with mission-critical operations that cannot afford any unplanned downtime have had on-site, standby emergency power (plus UPS) for years. Today, the financial loss associated with unplanned utility outages and/or utility "brownout" conditions has left more consumers looking into on-site standby power generation systems.

A facility owner who wants to include this as part of a strategic energy plan should conduct a preliminary evaluation of measures needed to maintain business operations in the event of an outage. From here, the economic impact of this standby power can be balanced against the potential effect of an unplanned utility outage to determine if it is the right solution.

10. Key Performance Indicators

Key performance indicators (KPIs), measured in MMBTU (1 million BTUs) per square foot per year, or dollars per square foot per year, are, simply put, baseline energy-consumption measurements.

Monitoring a facility's KPIs over its lifetime gives owners a way to track building performance relative to a baseline. KPIs can serve as a score card to continually benchmark against other facilities, determining the potential for efficiency improvements and to track progress of the overall energy reduction portion of the plan.

Building owners who wish to participate in a nationally based program to see how their facility's energy consumption compares to other buildings can participate in the federal government's ENERGY STAR® program. An energy-performance rating can be established by visiting (www.energystar.gov).

The 10 steps provided here to form a strategic energy plan offer you the direction you need to make sound utility infrastructure decisions. This dynamic process should be revisited at a minimum of every 5 years, or when major regulatory, political, and sociological events warrant.