Sprayed-in-place polyurethane foam (SPF) is a viable roof system that has been used for decades. Here, the pros and cons – broken down by different roofing characteristics – are outlined so you can make a better decision about SPF and whether it will work for your buildings.

Thermal Performance

No material has a better R-value per inch of thickness than urethane/polyiso foams. As rigid, faced, cellular boards, the aged R-value (long-term thermal resistance, or LTTR) is roughly 6 per inch. This excellent value is due to the choice of blowing agents and low density. SPF is at least equal to, or slightly better than, board stock in terms of insulating value since there aren’t joints between boards to conduct heat. Since fasteners don’t penetrate the spray foam, performance is 3- to 8-percent better than boards where heat flows through fasteners.

Dimensional Stability

As ASHRAE raises requirements for thermal resistance, we’re looking at 4 or more inches of board thickness. Isoboards can thermally warp when produced in thicknesses above 2 inches per layer, so at least two layers are needed. With SPF, several lifts can be applied within minutes to form a monolithic layer. The foam can be tapered or shaved to direct rainwater to the drains.

Flashing and Detailing

As photoelectric modules appear, the challenge is maintaining water tightness. SPF is self-flashing and can eliminate pitch pockets. It’s also suitable at roof-mounted curbs and parapets. The Spray Polyurethane Foam Alliance and the National Roofing Contractors Association indicate that, in most cases, no counterflashing is necessary.

Reflectivity

SPF systems require an elastomeric coating for UV protection. In most cases, a dark basecoat is applied to freshly applied foam. The heat absorbed by the dark coating evaporates moisture if dew forms overnight. Light-colored topcoats meet ENERGY STAR and code requirements for reflectivity.

Sustainability

Since weather protection is related to coating durability, it’s easy to recoat when pinholes appear. Impact damage is repaired by wiping the damaged area and applying a caulk that’s compatible with the SPF coating (silicone on silicone, urethane on urethane, or acrylic on acrylic). SPF is also suitable for direct application to weathered BUR and MB systems as a lightweight, new re-cover system, eliminating tear-off.

LEED calls for materials that can be obtained within a 500-mile radius of the construction site. The raw materials for SPF are liquids with densities of roughly 62.4 pounds per cubic foot. Upon expansion, the final density will be in the range of 3 pounds per cubic foot (expanding thirtyfold), making SPF remarkably efficient.

Environmental Issues

Concerns for atmospheric ozone depletion led to substitutes for CFC-11 (Freon® 11). Since Freon was non-toxic and fireproof, and possessed extremely low thermal conductivity, it was an ideal blowing agent for urethane foams. Second-generation blowing agents were called “hydrogenated chlorofluorocarbons,” such as HCFC 141b. When the EPA banned HCFC 141b, a third-generation material, HFC-245a (Enovate™ 3000), became available.

Attachment Options

SPF is self-adhering. On existing substrates, such as BUR and MB, the existing roof is either power-broomed or pressure-washed and vacuumed. When the surface dries, the existing membrane can be mechanically fastened to the deck to increase its wind-uplift resistance. Foam is then directly applied to the re-anchored roof system. For steel roof decks, a suitable underlayment, such as gypsum board, is mechanically attached to the deck, followed by the SPF and coating. SPF can also be sprayed directly to metal and tile roofs. Since SPF is monolithic, there are no seams to seal.

Fire and Wind Resistance

Most SPF/coating systems are UL Class-A over non-combustible decks and Class-B over combustible decks (when joints are taped or a suitable underlayment is applied). Because of SPF’s tenacious adhesion and air-tightness, wind resistance is a function of other elements, such as the nature of the roof deck.

Air Barrier Properties

SPF consists of small, minimum 90-percent closed cells. It has been used as a major retrofit tool for creating air barriers, such as where the roof deck meets the wall. In extremely high-humidity internal exposures, such as paper mills and bakeries, standard vapor retarders can be installed on the warm side of the roof system.

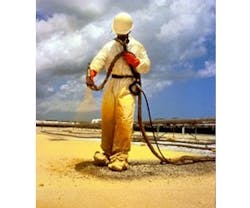

Construction Considerations

- Wind and surface moisture are major concerns during spray application. Windshields carried by robotic applicators help control overspray.

- The roof surface needs to be dry for the foam to properly react and cure. Specially formulated chemicals are available if application is necessary in extremely hot or cold climates.

- Minimum compressive strength is 40 psi – more than adequate for normal construction traffic.

- SPF requires less labor than other roofing systems and generates relatively little noise or dust during the roofing application.

About the Author

Richard L. Fricklas

Richard (Dick) L. Fricklas received a Lifetime Achievement Award and fellowship from RCI in 2014 in recognition of his contributions to educating three generations of roofing professionals. A researcher, author, journalist, and educator, Fricklas retired as technical director emeritus of the Roofing Industry Educational Institute in 1996. He is co-author of The Manual of Low Slope Roofing Systems (now in its fourth edition) and taught roofing seminars at the University of Wisconsin, in addition to helping develop RCI curricula. His honors include the Outstanding Educator Award from RCI, William C. Cullen Award and Walter C. Voss Award from ASTM, the J. A. Piper Award from NRCA, and the James Q. McCawley Award from the MRCA. Dick holds honorary memberships in both ASTM and RCI Inc.