Coordinated circuit protection enhances AC-LED luminaires and lamps (MAGAZINE)

This article was published in the June 2011 issue of LEDs Magazine. View the Table of Contents and download the PDF file of the complete June 2011 issue.

+++++

In recent years, LED technology has made impressive gains in price, performance and manufacturability, and further improvements that optimize LED operation are expected to drive exponential growth in the LED lighting market. Among the most recent commercial developments are AC-LEDs, which can operate directly on line voltage, without the need for an AC to DC converter. But even AC-LEDs are susceptible to line transients that can overheat the components, either causing immediate failure or greatly shortening the useful life of the LEDs. This article will describe a circuit-protection strategy that can help prevent overheating and deliver a reliable solid-state lighting (SSL) product.

When proper thermal management and circuit-protection design strategies are employed, AC-LED technology offers several advantages over conventional lighting, including compact size, component count reduction, energy efficiency, and reduced system cost. But lamp and luminaire designers must design to protect against over-voltage, over-current, and over-temperature conditions.

SSL designs may need a second protection device for over-current and over-temperature conditions. In both AC-LEDs and DC-LEDs alike, excessive heat at the LED junction can dramatically reduce both the light output and lifespan of the LED.

Thermal runaway design considerations

To understand the circuit-protection needs, let’s consider the potential problem with LEDs due to the fact that they exhibit a negative thermal coefficient. The LED forward voltage (Vf) decreases with increasing temperature. With a constant-voltage power supply, increasing the temperature slightly decreases Vf and increases the current by a relatively large amount. This causes a net increase in power and an increase in temperature. For a given thermal path, the heat transfer may no longer be able to accommodate the increasing power.

In extreme cases, the result is thermal runaway, which may damage the AC-LED if the current or power is not limited to prescribed levels. The LED light output varies roughly linearly with the current passing through the LED, within a specified current range. If the current exceeds the manufacturer’s recommendations, the LEDs can become brighter but the light output can degrade at a faster rate due to lumen depreciation, shortening the useful life of the component.

| Input voltage (V) | 70 | 80 | 90 | 100 | 110 | 120 | 130 | 140 | 150 |

| Current (mA) | 11 | 13 | 22 | 33 | 44 | 52 | 68 | 86 | 103 dropped to 13 |

| Temperature (°C) | 26 | 29 | 36 | 49 | 64 | 79 | 102 | 128 | 142 |

| Light output (lux) | 110 | 430 | 1010 | 1710 | 2320 | 2950 | 3550 | 3800 | 4000 dropped to 420 |

2. Temperature is junction temperature.

3. Test results will differ with different resistors, thermal design and ambient temperature.

TABLE 1. Test results from a Seoul Semiconductor AN3211 LED with PolySwitch miniSMDC014F protection, using the test setup shown in Fig. 2.

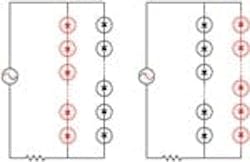

Let’s examine an SSL design based on the AN3211 AC-LED from Seoul Semiconductor (Fig. 5). Externally, the LED is treated as an AC-driven component that requires a combination of external resistors to set the operating current based on its forward voltage. The LED’s internal construction consists of two sets of diodes in parallel that are of opposite polarity. As shown in Fig. 1, as the line voltage increases on the positive half-cycle, one of the internal strings conducts and generates light; during the negative half-cycle, the other string conducts and generates light.

Fig. 2 shows the Seoul Semiconductor AC-LED AN3211 test setup, where an MOV and a PolySwitch miniSMDC014F PPTC device were integrated on the AC-LED lighting-system board. The MOV serves to limit damage from voltage spikes while the PPTC protects the LED from current and temperature faults.

Over-voltage protection design considerations

Fig. 3 and Fig. 4 show test results on the AN3211 protected with a 7-mm, 200V MOV when lightning and ring-wave tests are applied to the lighting circuit. As seen from the results, the MOV solves lightning and ring-wave issues by damping the surges. Also, the light output is very stable during lightning surge and ring-wave testing. This approach helps equipment remain operational after specified lightning tests according to IEC 61000-4-5 and ring-wave tests according to IEEEC.62.41.

AC-LEDs have been used increasingly in general-purpose Illumination systems for indoor and outdoor use. Although the AC systems offer excellent reliability and design benefits, they also require robust protection to meet safety and performance standards.

Design risk can be minimized by pairing a PPTC over-current/over-temperature protection device with an MOV to provide a completely-resettable and coordinated circuit-protection solution. New products in development by Seoul Semiconductor include over-current, over-voltage and over-temperature protection provided by TE Circuit Protection’s AC 2Pro device. This hybrid device combines a PPTC element with an MOV in one thermally-protected device, and gives designers flexibility and the convenience of integrated protection in a single device.