Custom LED displays for instrumentation and message panels

The arrays are based on two different technologies, hybrid and monolithic, depending on the application, although there is some cross-over where displays using a monolithic LED chip are packaged with controlling or matching hybrid electronic components.

Hybrid displays

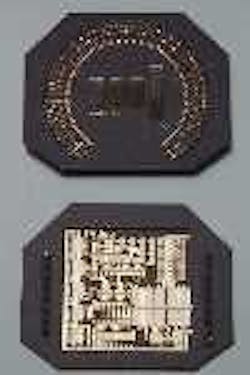

As single LED die are used, it is possible to mix and match any of the wide range of LEDs that are now available, and so multi-colour displays with blue, green, amber or red emitters can be made. Figure 1 shows an example of an amber circular display showing the patterns on the front (LEDs) and rear (drive electronics) of the package together with the fully-illuminated display. This particular device, in addition to acting as an analog display, can also show the measured value as a rolling-digit digital display.

Monolithic arrays

These are multi-element emitters on a single chip with each of the emitters having a separately addressable connection (usually the anode) to allow it to be driven independently, and a common (cathode) return connection. The emission areas can vary in size from a few microns across, while the formats and spacings that can be produced depend on the need for contact metallizations to make contact to the emitting regions.

Obviously a separate connection and hence wire bond for each element is required and therefore the wire bond pad layout is usually the factor that limits the size of a chip. To overcome this limitation, XY matrix addressable arrays are currently under development.

The LED chips can be mounted into a variety of packages depending on the intended use, and this can include optical components (such as lenses etc) and/or electronic components to provide local LED drivers or output matching. The emission levels across an array are usually matched to within a few percent as processed, but this can be improved by the inclusion of either active matching using previously stored coefficients, or passively by the use of pre-determined resistor networks. Examples of various types of device and packages are shown in Figure 5.

Most applications of monolithic arrays use one or two chips per unit, but for some printing applications, wide print bars are required. In Figure 7 we can see such a unit. This particular example is 20 inches wide with emitters spaced at 600 dpi. Individual linear arrays are assembled end to end to maintain the 600 dpi spacing along the full length of the bar.