Back in February 2014, we discussed the need for adequate R-values to meet current building and energy codes. Buildings in the mid-continent United States with all above-deck thermal insulation require an R-factor of 20 – dramatically more than during the pre-oil embargo years of perhaps R-2.8 for 1 inch of wood fiber or perlite boards.

A combination of polyisocyanurate and cover board is much more typical today, with a half-inch cover board contributing an R of 0.56 and the isoboard contributing the rest. With the recently revised R of 5.6 per inch of isoboard’s thickness, we now need roughly 3.5 inches of isoboard to meet code.

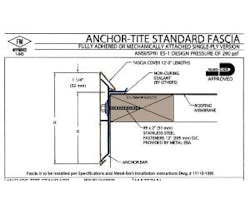

I also reminded you that low slope roofs need wood nailers at roof edges and penetrations that match up to the above thickness of 3.5 inches of isoboard, plus the half-inch of the recover gypsum board.

Ironically, a 2-by-4 is really only about 1.5 inches thick, so we need two 2-bys plus a 1.25-by to match up to the nominal roof thickness.

To understand where we seem to be heading, it may be helpful to see where we are coming from.

The Early Years

Creosote was originally used as a wood preservative. Derived from coal tar pitch, creosote is the most widely used wood preservative in the U.S. but is falling out of favor, as the EPA now considers it a probable human carcinogen.

The next generation of preservatives was based on chromated copper arsenate (CCA), which is now being phased out to reduce potential exposure to arsenic, also now considered a potentially toxic substance.

However, recent years have seen the development of several water-based alternatives to CCA treatments:

- ACQ: A class of preservatives containing copper oxide and a quaternary ammonium compound.

- Borates: These low-toxicity alternatives have been used for more than 70 years. Borates naturally occur in trace amounts and are non-volatile when formulated for use as wood preservatives, so no off-gassing occurs.

- Copper azole: Typically used to treat softwood lumber from sources such as southern pine, red pine, ponderosa pine, hem fir, and Douglas fir.

- Cyproconazole: Specifically for above-ground applications, cyproconazole is not intended to protect wood that comes in contact with the ground.

- Propiconazole: Like cyproconazole, propiconazole prevents wood decay in above-ground applications only.

Richard (Dick) L. Fricklas, received a Lifetime Achievement Award and fellowship from RCI in 2014 in recognition of his contributions to educating three generations of roofing professionals. A researcher, author, journalist, and educator, Fricklas retired as technical director emeritus of the Roofing Industry Educational Institute in 1996. He is co-author of The Manual of Low Slope Roofing Systems (now in its fourth edition) and taught roofing seminars at the University of Wisconsin, in addition to helping develop RCI curricula. His honors include the Outstanding Educator Award from RCI, William C. Cullen Award and Walter C. Voss Award from ASTM, the J. A. Piper Award from NRCA, and the James Q. McCawley Award from the MRCA. Dick holds honorary memberships in both ASTM and RCI Inc.

The presence of copper atoms in these wood preservatives is of concern, especially where steel fasteners are used to anchor fascia and gravel stops. The National Roofing Contractors Association (NRCA) recommends against using copper-rich treated wood due to the possibility of accelerated corrosion between the steel fasteners and ACO or any of the other copper-rich preservatives. (Learn more about this phenomenon at spri.org – click on SPRI Standards & Technical Reports and choose “Evaluation of Metal Fasteners Corroded from Contact with Preservative Treated Wood” under the Technical Reports heading.)

However, there is another alternative – avoiding wood completely. One such strategy involves the EdgeBox, an engineered metal replacement system for wood blocking at roof edges. Using substitutes for wood allows you to avoid copper and arsenic entirely; you can also sidestep thickness issues by purchasing products manufactured to your desired thickness.

Meet R-Value Needs with Wood Insulation

The ins and outs of wood roofing.

Getting the Edge on Roofing

Learn more about potential issues between wood nailers and metal roof edge details.

Maximize Roof Service Life

How smart analysis raises the ceiling on your roof’s value.

About the Author

Richard L. Fricklas

Richard (Dick) L. Fricklas received a Lifetime Achievement Award and fellowship from RCI in 2014 in recognition of his contributions to educating three generations of roofing professionals. A researcher, author, journalist, and educator, Fricklas retired as technical director emeritus of the Roofing Industry Educational Institute in 1996. He is co-author of The Manual of Low Slope Roofing Systems (now in its fourth edition) and taught roofing seminars at the University of Wisconsin, in addition to helping develop RCI curricula. His honors include the Outstanding Educator Award from RCI, William C. Cullen Award and Walter C. Voss Award from ASTM, the J. A. Piper Award from NRCA, and the James Q. McCawley Award from the MRCA. Dick holds honorary memberships in both ASTM and RCI Inc.