Packaged Terminal Air Conditioner Guide

Building wall systems would work great, if it weren’t for all the holes we put in them.

One of the leading examples of these holes is caused by the packaged terminal air conditioner (PTAC), most common in hotels and multifamily buildings. PTACs are permanently installed, through-the-wall units designed to cool or heat individual rooms. Design and construction methods involving PTACs vary, but all too often, they allow water leakage into the building.

No matter what the causes of water may be, fundamental principles of wall waterproofing can be applied to PTAC installations to produce reliable and durable solutions.

Internal Water Management of PTACs

The condensate pan of the PTAC chassis can drain to the sill of the surrounding sleeve by either overtopping if condensate is excessive, or through a valve in the sill of the chassis that is activated by low temperature to prevent frost forming on coils. Water also enters the sleeve sill directly from water penetration through the louver.

Water in the sill of the sleeve is intended to drain by one of two methods: either through drain lines in the bottom of the sleeve that connect to conduits within the building that conduct the water out of the building at lower elevations, or through weep slots in the upturned front edge of the sleeve and out through the louver or louver framing system, depending on the methods of louver installation.

Inadequate Manufacturer Guidelines

Manufacturer’s instructions generally include written guidelines and schematic figures to guide installation of the wall sleeve and other PTAC components. In many cases , these instructions fail to show fundamental waterproofing components of the exterior walls and therefore fail to provide proper guidance for integrating the wall sleeve with the exterior wall waterproofing. Make sure there is proper detailing from the designer and coordination among the trades to ensure the system is effective.

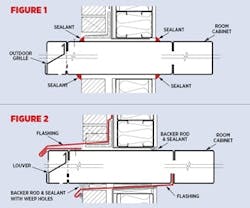

A typical schematic figure (Figure 1) depicts a section through a brick veneer wall and shows, from exterior to interior: brick veneer, drainage cavity, wall sheathing, wall framing, and interior wallboard. The brick veneer above the PTAC sleeve penetration is supported by a steel lintel.

The sketch omits the water resistive barrier on the exterior sheathing, flashing on the steel lintel above the PTAC, as well as flashing beneath the PTAC – all elements that are required for reliable and durable water penetration resistance. The manufacturer’s recommended waterproofing consists solely of sealant at the perimeter of the PTAC sleeve penetration on the exterior and interior. Manufacturers generally require the wall sleeve to project beyond the outboard face of the wall from one-quarter to five-eighths of an inch. PTAC installations rely on the watertight construction of the wall sleeve to collect wind-driven rain that penetrates the exterior louver as well as condensate that drains from the condensate pan.

Some PTAC manufacturers require the wall sleeve to be pitched to the exterior; some require the wall sleeve to be installed level. Manufacturers call for flashing beneath the PTAC sleeve only where a sleeve extension is required for deep wall sections, which protects against leakage through the joint between the PTAC sleeve and sleeve extension. The flashing details typically show end dams but no upturned leg at the interior, and no slope toward the exterior. PageBreak

Deficient Design Drawings

Construction drawings often fail to provide proper direction for integrating the wall sleeve with exterior wall waterproofing. Ensure your designs include essential elements that avoid failures.

Even when designs show a fundamental waterproofing component such as a flashing beneath the PTAC sleeve, the flashing generally lacks a panned-up leg at the interior and end dams to collect water that penetrates the back-up wall construction.

The drawings generally fail to provide sufficient detail, such as blown-up section details or isometric views of flashing terminations and other complex transitions, to guide the installation of a water-resistant assembly.

Three Typical Water Leakage Problems

Water leakage paths associated with PTAC installations include: through the joint between the inboard surface of the louver and the front face of the PTAC sleeve, through unflashed perimeter joints between the louver or sleeve and the adjacent wall cladding, and through unsealed corners of metal sleeves (plastic sleeves are molded and do not have vulnerable corners).

Be mindful of these leak sources and how to combat them:

1) Leakage through Interface of Louver and PTAC Sleeve

Louvers shed water toward the outside but do not prevent the entry of wind-blown rain or rain drawn into the assembly by the PTAC fan. Some of the water bypassing the louver flows against the joint between the louver and the sleeve, and some flows into the sleeve.

The joint between the inboard face of the louver and the sleeve is inherently vulnerable to leakage. Manufacturers recognize this vulnerability and typically stipulate that this joint be placed outboard of the wall system by at least one-quarter inch to allow leakage to fall harmlessly outside the face of the wall, as explained above. This method, however, ignores the typical architectural requirement that louvers be set flush with, or slightly recessed from, adjacent wall surfaces.

When the louver is set flush or recessed, the vulnerable joint ends up inside the wall. Sometimes there is an attempt to seal this joint though the use of double-stick tape, foam, or glazing tape, but the surfaces that mate are irregular and often have sleeve fasteners that obstruct or penetrate these seals, rendering them ineffective.

Many sleeves are designed to drain condensate through weep slots in this outboard edge of the sleeve, directly through this seal between the louver and sleeve. Some installations include birdscreens inboard of the louver, and in some cases the birdscreens are sandwiched between the louver and the PTAC sleeve, creating an open pathway for leakage.

Since leakage through the louver-to-sleeve joint results from both rain penetration and condensation, this path of leakage can occur even in the absence of rain.

Secure protection of the building from this path of leakage requires a full pan flashing unless the louver-to-sleeve joint is placed outboard of the exterior wall face (see Figure 2).

2) Leakage at Perimeter of PTAC Sleeves

PTAC sleeves often lack perimeter flashing around the wall opening. In the absence of a perimeter flashing, the installation relies solely on continuous adhesion of sealant between the wall cladding and the wall sleeve to prevent water entry.

Gaps or loss of bond in the sealant – which result from improper sealant installation, incompatible materials, joints in substrates, sealant degradation due to exposure to the elements, and other causes – are inevitable and result in water penetration to the interior. This path is often a source of profuse leakage.

Even if the perimeter sealant is completely effective for a period of time, in the absence of head flashing, water draining down within the wall assembly above the unit can be deflected to the interior by the sleeve, which interrupts the downward flow of water.

3) PTAC Sleeve Leakage

Drainage of water from the sill of the sleeve is either internal or through weep slots as noted above. If internally drained, the sleeves are generally installed level. Since the sleeves don’t pitch to the internal drains, there is usually some residual water that does not drain out. The water can become stagnant, fostering organic growth.

The problem of ponded water is exacerbated if the sleeve deflects due to insufficient support for the sleeve and chassis. The problem of sleeve deformation is particularly acute with plastic sleeves that creep over time.

With both forms of sleeve drainage, some ponding is common; thus the watertight integrity of the sleeve sill corners is critical to avoiding leakage to the interior floor.

Plastic sleeves have molded corners which are reliably watertight unless damaged. Metal wall sleeves typically have a return flange at the interior that is cut and lapped at the corners. The lap joint is covered with sealant to prevent ponding water in the sleeve from leaking to the interior. The sealant-to-metal bond tends to degrade over time when exposed to prolonged ponding conditions.

Lack of proper pitch together with reliance on sealants results in leakage at the corners of the wall sleeves, causing deterioration of interior finishes adjacent to and below these sleeve corners.PageBreak

Fundamental Waterproofing Concepts

Unfortunately, fundamentally sound, time-proven waterproofing concepts are generally absent from manufacturers’ standard details and most architectural designs. PTAC wall sleeves require perimeter flashings for reliable and durable performance, whether installed in curtain walls, cavity walls, or barrier walls.

The following design guidelines are recommended to avoid PTAC leakage.

Perimeter Flashings

PTAC designs, like the designs of other exterior wall penetrations, need to recognize the inherent lack of reliability and durability of perimeter sealant joints. The design should provide flashings to collect water that bypasses the perimeter seals and drain it to the exterior.

- Sill: The sill should have a metal flashing that extends the full depth of the wall sleeve, with an upturned leg inboard of the wall sleeve, end dams at the sides of the wall sleeve, and a down-turned drip edge that projects beyond the outer face of the exterior wall. The metal flashing should be properly integrated with adjacent wall materials beyond the PTAC opening.

- Head: Because the PTAC sleeve cannot provide proper support to the brick above the sleeve penetration, the brick is supported by a loose steel lintel. A metal flashing with drip edge projects outward beyond the top of the louver and engages a continuous metal hook strip fastened to the wall sleeve and embedded in sealant. The metal flashing covers the horizontal leg of the lintel, turns up at the vertical leg of the lintel, and extends upward onto the exterior wall sheathing. The water barrier laps over the vertical leg of the metal flashing. The metal flashing should have end dams that turn up into a masonry head joint beyond the PTAC opening.

- Jamb: The water barrier should extend into the wall opening the full depth of the wall, and lap over the end dam of the sill flashing below.

Flashings at Curtain Walls and Window Walls

Flashing concepts for PTACs installed within curtain walls or window walls are similar to those outlined for cavity wall systems. The flashings must drain either directly to the exterior face of the wall, or into a glazing pocket that is wept to the exterior. For flashing installations where drainage into the glazing pocket might overwhelm the glazing pocket weep holes, the sill pan should project beyond the outer face of the wall to drain water outboard of the glazing pocket.

Slope to Drain

One of the most fundamental concepts of good waterproofing practice is to provide adequate slope to promote prompt drainage from waterproofing surfaces and avoid ponding water conditions. A slope of one-quarter inch per foot, a minimum requirement for roof slopes, should be provided for PTAC wall sleeves. It may be necessary to provide leveling shims for the chassis to meet the manufacturer’s requirements for the levelness of the chassis. Adequate slope to drain will reduce the exposure of inboard wall sleeve corners to ponding water and subsequent leakage.

Ensure Proper Design and Installation

PTACs are a common source of water infiltration through exterior walls. Installation instructions typically provided by the manufacturers and the details on most design drawings ignore fundamental principles of wall waterproofing. PTACs installed in accordance with these instructions and designs without due consideration of fundamental wall waterproofing principles are prone to leakage.

However, PTAC leakage can be minimized through proper design and construction, including the following:

- Recognize the inherent lack of reliability and durability of perimeter sealant joints. Provide perimeter flashings at the sill, head, and jambs of the PTAC opening that integrate with the back-up water resistive barrier (cavity walls) or other secondary waterproofing and drainage system (glazing pockets of curtain walls or window walls).

- Install PTAC wall sleeves with slope to the exterior to promptly drain water to the exterior. Shim the PTAC chassis to meet the manufacturer’s requirements for levelness.

Make sure your PTACs are designed and installed to withstand a PTAC attack.

Thomas A. Schwartz is the president and a senior principal, Mark A. Brown is a senior project manager, and Octavian Vlagea is a Senior Staff II at Simpson Gumpertz & Heger Inc., an engineering firm that designs, investigates, and rehabilitates structures and building enclosures.