LED Efficiency Droop

As many facility managers and building owners are aware, LEDs seem to reach a point where more electricity no longer imparts the same kick and productivity levels-off. But there may be some very interesting developments on the way that will lead toward more affordable and efficient LED options. Researchers from California and Japan have devised a new design for green and blue LEDs that avoid much of this LED efficiency droop.

By changing the orientation of the crystal structure in semiconductor films, the team created LEDs with high efficiency and extremely low droop. Droop, which is a dramatic drop in efficiency at high currents, is one of the main problems limiting the growth of the solid-state lighting market.

Blue and green LEDs provide the essential hues that blend with other wavelengths to give us the familiar white light we expect from household bulbs. These highly prized colors, however, have been among the hardest to engineer and the "droopiest" of the LEDs.

"We believe this technology could be a big breakthrough and has the potential to change the future of lighting," says Yuji Zhao, a graduate student at the Solid State Lighting and Energy Center at the University of California Santa Barbara (UCSB) and one of the lead researchers on the team.

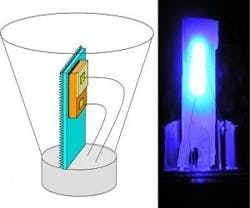

LED chips are made from layers of doped semiconductors sandwiched together. When a voltage is applied across the layers, electrons and holes (an absence of electrons) migrate toward an area of the LED called the active layer, where they combine, begetting a photon in the process. In most commercially available blue LEDs, the crystals that make up the semiconductor layers are grown in a flat orientation called the c-plane. This traditional orientation of the crystals, however, may create electrical fields that interfere with the reunion of the electrons and holes.

The UCSB researchers' LEDs have non-traditional, tilted crystal orientations that lessen the effect of the field, and exhibit some of the lowest reported measures of droop. Using this approach the team was also able to fabricate LED chips that are smaller than standard commercial LEDs, which could cut down on manufacturing costs.