Too many variables!

Those of us who are deeply involved in the roofing industry recognize that there are far too many fragments and parties involved in designing and installing a roof system.

Who Offers What?

Material producers, of course, will focus on their product. Some producers offer a single component, such as EPDM, PVC, modified bitumen, standing seam metal, closed cell polyisocyanurate foam, or BUR. But because none of these producers provide treated wood for roof perimeters or curbs, they will tread lightly on that, perhaps referring to SMACNA or some other trade association for adequate information. Of course, these days, based on recommendations from the National Roofing Contractors Association (NRCA) and savvy specifiers, Ammonium Copper Quaternary (ACQ) treated wood nailers should be used only with special fasteners. It may be better to use untreated wood at curbs and roof perimeters.

Roofing contractors, for the most part, do not furnish roof drains, skylights, or carpentry. With photovoltaic (PV) systems appearing on our roofs, licensed electricians will join the crowd during installation. For vegetated roofs, landscape designers and installers will be there too. While these contractors certainly know their trades, they may not be as familiar with the niceties of roofing.

Deck installers may specialize to fit their market. On the West Coast, plywood or OSB may be installed over wood joists, with flexible faced glass fiber batts installed under the deck. Others may limit their installations to precast concrete, or perhaps cast-in-place, or lightweight insulating concrete.

Membrane roof systems may be attached to a building in a number of ways:

- Fully adhere all components from the deck on up using one or another of asphalt, solvent-based adhesives, water-based adhesives, self-adhesion, spray-in-place foam, or torch application methods.

- Partially attached, using various screws, intermittent ribbons of adhesives, and batten bars.

- Loose laid and held down with ballast.

- Inverted roof systems (also known as protected roof membranes or PRMs) where the membrane is installed on or close to the roof deck and most or all of the thermal insulation covers the membrane. The insulation, in turn, is ballasted with filter fabric and coarse stone or pavers.

- Vegetated roofs can be considered a version of a PRM. These vegetated roofs and photovoltaics (PV) could, in turn, be ballasted or fully adhered.

The Roof Designer’s Challenge

When we then consider the options in seaming – using tapes, heat welds, or various adhesives, choosing between air barriers or vapor retarders, and factoring in surfacing and deck choices – it becomes a major assessment challenge for the designer.

The designer will look at structural considerations, the unique variables such as wind and hail resistance, snow drifting, drainage, fire resistance, and code compliance. Here again, material manufacturers walk gingerly with respect to design criteria.

Other decisions are needed on parapets and treated wood for edging and curbs. While low roof edges may be adequately specified and installed by roofing contractors, masonry walls with imbedded through-wall flashing require coordination of masons and sheet-metal installers.

With all these variables, a relatively new concept, the “weakest link,” can be very attractive. It requires you to acquire quite a bit of field data and use various test devices and field observations to “separate the men from the boys.” For example, if we observe that most roof blow-offs start at the roof edge, we should design details and select materials that are strengthened so that edge failure is far less likely. Strengthening to meet this concern will cost more, but the edge may no longer be the likely weakest link.

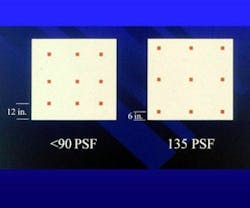

In the design of roof systems, we know wind forces are greatest in the corners of a roof, somewhat less along the roof perimeters, and less still in the “field” of the roof.

Many building codes, ASCE-7, FM Global Property Loss Prevention data sheets, and RCI documents all use mathematical modeling, wind tunnel studies, or simplified tables to estimate what the wind uplift forces will be in these zones. When roof fasteners are part of the design, we would use most fasteners in the corners, more in perimeters, and the usual amount in the field. In some cases, we use mechanical fasteners everywhere but the corners, where only fully adhered systems can meet the needed higher wind uplift resistance.

Where to Look

One recent document with all of the above in mind is A Guide for the Wind Design of Mechanically Attached Flexible Membrane Roofs, published by the Institute for Research in Construction, National Research Council of Canada. For example, many variables can be tested in various combinations – see above.

Commercial and industrial property insurer FM Global and its independent product testing and certification business, FM Approval, takes this consideration much further:

At FM Global, we believe the majority of all property loss is preventable. By working in partnership with clients and applying our comprehensive approach to commercial and industrial property insurance, we strive to support broader risk management needs and protect the value created by our clients businesses worldwide through

- Risk identification and assessment

- Risk avoidance and reduction

- Risk acceptance and transfer

Roughly 5 years ago, FM recognized that FM data sheets were being cited even though the building was not going to be insured by FM. Rather than restrict FM’s knowledge to only FM clients, FM materials were made available to the construction industry at large, including such organizations as the Corps of Engineers and private design firms.

All roofing-related FM Global Property Loss Prevention Data Sheets and all tested constructions are posted online for reference at no cost at RoofNav.com. Roofing and non-roofing-related data sheets also are available at www.fmglobaldatasheets.com. Online registration is all that’s required to access either resource.

FM Global’s research campus in Rhode Island boasts the world’s largest center for property protection research, product testing, and education. Specific construction systems are tested, with all of the above components completely detailed.

- Most readers will be aware that FM Approvals, a business unit of FM Global, conducts fire tests as part of its product certification process for all approved roof systems, with the tested assembly designated as non-combustible, Class 1, or Class 2.

- Wind uplift resistance is tested using a 5-foot by 9-foot pressure frame for fully adhered systems. For mechanically fastened single ply systems, where spacing of fasteners may be in rows as much as 10 feet apart, a larger 12- by 24-foot frame can be used. This would also be the case for metal roof systems, where the purlins are generally 5 feet apart and the small frame would have an edge effect on uplift ratings.

- If wind-blown debris breaks windows during a weather event, the building may experience increased internal pressure, causing blow-offs. FM's missile impact cannon imitates the force of wind-blown debris to evaluate various means of protecting against this pressurization.

FM Approvals also works in cooperation with other roofing institutions, such as SPRI (Single Ply Roofing Industry) and RICOWI (Roof Industry Committee on Weather Issues) and recently installed an ANSI/SPRI ES-1 device for testing roof edging and coping.

Perhaps the greatest strength of these cooperative efforts on testing complete systems lies in the easy access to RoofNav. By starting with weather data and a description of the contemplated building, the designer can assemble a complete roof design step by step. Each construction has a unique identifier code that lists each and every component that has been tested for the contemplated construction.

Data sheets from the organization, which are available through RoofNav, provide information on many roofing topics, including:

- 1-28 Wind Design

- 1-28R Roofing Systems

- 1-29 Roof Deck Securement and Above-Deck Roofing Components

- 1-30 Repair of Wind Damaged Roof Systems

- 1-31 Metal Roof Systems

- 1-32 Existing PVC Roof Covers

- 1-35 Green Roof Systems

- 1-49 Perimeter Flashing

By combining the general requirements of the FM data sheets, the ANSI/SPRI documents, or both with the approved combinations of components in RoofNav, we can, at last, assemble the big picture.

Richard (Dick) L. Fricklas was technical director emeritus of the Roofing Industry Educational Institute prior to his retirement. He is co-author of The Manual of Low Slope Roofing Systems and continues to participate in seminars for the University of Wisconsin and RCI Inc. - The Institute of Roofing, Waterproofing, and Building Envelope Professionals. His honors include the William C. Cullen Award and Walter C. Voss Award from ASTM, the J. A. Piper Award from NRCA, and the James Q. McCawley Award from the MRCA. Dick holds honorary memberships in both ASTM and RCI Inc.

Tips for Selecting Rigid Roof Insulation

The best roof insulation choice meets thermal needs, energy codes, and performance requirements, resulting in a roof system that performs well over the long term.

Metal Roofing: A Cool Choice for Any Building

Reduce cooling and heating energy usage with cool metal-roofing systems.

Roofing Lifecycle Costs Emerge

Energy efficiency and long-lasting roofs contribute to lower roofing life-cycle costs - an impact that goes directly to your bottom line.

About the Author

Richard L. Fricklas

Richard (Dick) L. Fricklas received a Lifetime Achievement Award and fellowship from RCI in 2014 in recognition of his contributions to educating three generations of roofing professionals. A researcher, author, journalist, and educator, Fricklas retired as technical director emeritus of the Roofing Industry Educational Institute in 1996. He is co-author of The Manual of Low Slope Roofing Systems (now in its fourth edition) and taught roofing seminars at the University of Wisconsin, in addition to helping develop RCI curricula. His honors include the Outstanding Educator Award from RCI, William C. Cullen Award and Walter C. Voss Award from ASTM, the J. A. Piper Award from NRCA, and the James Q. McCawley Award from the MRCA. Dick holds honorary memberships in both ASTM and RCI Inc.