Building on last month’s article, The Walkthrough Survey for an Energy Audit, we now will explore some of the more advanced auditing and reporting techniques. Not all of these ideas will be appropriate for every facility, but many will help to move your energy projects forward.

Data collection and analysis become a more important factor when doing a Phase II level report, which includes recommendations and priorities for energy investments. There are numerous tools and instruments for a good energy survey, and some of these tools can be expensive. However, they usually pay for themselves with the energy savings they help to identify.

If you want to really understand a system, putting data loggers on facility equipment is a good idea. Data loggers are relatively inexpensive (about $100 each) and you can put them next to motors, compressors, lights and many other systems to determine when the machines are turning on/off and other operational data over long periods of time. Some energy auditors will put loggers on equipment at the beginning of their survey and collect them later (1 day to 3 months) to validate their assumptions. Collecting and displaying data is a good way to test theories of how the building is actually operating.

Another inexpensive device is a light meter to determine lighting levels in different areas of a building. Areas in many buildings are over illuminated based on standards set by the Illuminating Engineering Society of North America. The light meter data can be very convincing.

I believe that a picture is worth a 1,000 words, so I advocate using a camera to document what you find during an energy survey. Photos and videos can capture an operation, show an opportunity, and avoid a debate.

In a recent survey, I took video of a facility that had its lights on during the evenings and weekends when no one was present within the facility. Another video shows compressed air leaks in a de-activated area of a plant. You can watch these videos here: http://www.profitablegreensolutions.com/video-sample

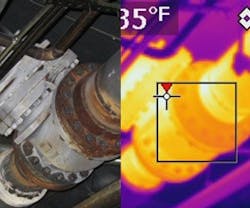

An infrared camera is a tool that shows where heat is being lost within a facility. You can use these images to explain the value of insulation to almost any CEO because the picture really makes the point. Although an inexpensive infrared camera might cost several thousand dollars, I believe the cost is worth it because it reveals hot spots in electrical equipment and fuses that may be ready to fail and may cause an unplanned facility shutdown.

If you do a lot of surveys on facilities with boilers, a combustion analyzer is a very helpful tool. You basically insert a probe into the exhaust stack of the boiler and measure the characteristics of the gas to determine the efficiency of combustion. In the hundreds of audits that I have done, we almost always find savings opportunities with the boilers, and the measurements allow us to quantify the savings. It is really surprising how many facilities do not have automatic combustion tuning equipment when nearly all highway vehicles have combustion analyzers. When you consider the fuel costs of a large boiler – which are much larger than your average car fuel expenses – a 1-3% savings can pay for combustion controls in less than a year.

If you are looking at a building with steam pipes or compressed air lines, ultrasonic leak detectors can help you find leaks even while the plant is operating and creating noise. Both steam and compressed air leak detectors are about the size of a brick and can be carried around a plant while wearing earphones and pointing a probe in different directions. During one audit of an automobile manufacturer, I identified $1.6 million in savings from air leaks. The payback to fix the leaks was less than 2 months.

Reporting the Results

There are many ways to present your findings from a survey. I recommend using as many videos and photos as practical and to write a concise, 1-page executive summary. In the executive summary, be sure to highlight the benefits of the findings in your report not the details – if you are an engineer, this may be easier said than done! Use a headline (just like in the newspapers), to capture the CEO’s and CFO’s attention and let them know why they can’t miss reading your report. You can download a sample executive report for one of my recent clients here: http://www.profitablegreensolutions.com/sample-exec-summary.

Ultimately, the effectiveness of the entire energy audit depends on whether or not improvements are implemented … and that depends on whether or not people like the idea … and that depends on if they actually read the survey report! Utilizing the data collection tools mentioned above can help. You can also create a separate PowerPoint presentation so you can engage and interact with your audience.

Eric Woodroof, Ph.D., is the Chairman of the Board for the Certified Carbon Reduction Manager (CRM) program and a board member since 1999 of the Certified Energy Manager (CEM) Program. He is a strategic advisor, corporate trainer, keynote speaker, and founder of ProfitableGreenSolutions.com.