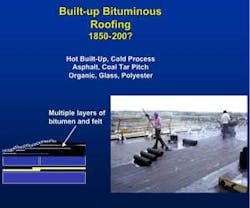

The granddaddy of membrane roofing is built-up bituminous roofing (BUR). BUR continues to hold a modest place in the market – certainly not what it was in the 1970s and 1980s, but still significant.

With increased interest in sustainability and green buildings, it’s only fair to look at the issues and see where BUR stands.

First, in terms of recycling, BUR was (and is) about as green as it gets. Asphalt is a byproduct of converting petroleum into gasoline, diesel, mineral spirits, and heating oil. It’s the bottom of the barrel, making it cost effective for large volume usage, such as paving and roofing. Coal-tar pitch is a byproduct of processing coal into coke. (Coke is used in producing carbon steel and in electrodes for aluminum production. Both asphalt and coal tar pitches are classified in the United States as bitumen.) Both can be heated and used as saturants and coatings for felts, and reheated to serve as a hot-melt adhesive during construction of the roof membrane.

The reinforcements for BUR are recycled paper (for organic felts) or recycled glass (glass fiber mats). While there are now synthetic underlayments for steep roofing, No. 15 and No. 30 asphalt saturated roofing felt are still the standard underlayments for asphalt shingles, metal panels, and slate and tile roofs. On a nationwide basis, asphalt shingles with glass fiber reinforcements dominate the market. Warranties on many of the laminated shingles are for 30 years or more, but warranties are likely to be voided if PV panels are mounted directly on and through the shingles.

The basic thermal insulations used with BUR have traditionally been wood fiber, glass fiber, and perlite fiber boards, all of which contain significant amounts of recycled materials. For the higher thermal resistance needed today, polyisocyanurate foam (isoboards) with compatible facers are used, since the isoboards can resist the heat of hot-applied asphalt or the solvents used in cold-process roofing.

As an alternative to board-stock insulation, lightweight insulating fills can be used (generally to provide slope to drain, a feature that’s likely to take on more significance with photovoltaic roof systems). To achieve the high thermal resistance needed, expanded or extruded polystyrene boards are imbedded in the cementious fill. A coated base sheet can be spot-attached or nailed to the fill, followed by conventional hot asphalt application.

You may have seen bumper stickers that say, “Asphalt is 100% recyclable.” This is true for the paving industry, where the existing asphalt paving is ground up, blended with additional bitumen, and reinstalled in situ. Asphalt shingles are also recycled, and even BUR can be given a new life as asphalt curbing, walkways, and similar applications.

Traditional surfacing for BUR has been a flood coat (around 60 pounds of asphalt per roofing square) into which aggregate (stone or slag) is embedded. The bitumen serves to help waterproof the roof membrane while the aggregate serves as a stabilizer (so the flood coat won’t flow), a UV screen, and a fire-resisting surfacing. (Multiple-ply BUR with a gravel surfacing meets Class-A fire requirements.) This system also stiffens the membrane against wind uplift.

A BUR membrane back in the 1930s or 1940s might have consisted of two No. 15 asphalt saturated felts laid dry on a nailable roof deck, followed by three more felts imbedded in hot asphalt. This evolved into an asphalt-coated base sheet, replacing the two dry ply sheets, with that base sheet either nailed or mopped depending upon the substrate.

That “base plus three” or a straight 4-ply membrane (but using glass fiber ply sheets) is used as the standard 20-year roof, while one ply less may be warranted for 15 years. Another innovative option is to install a conventional 3-ply glass fiber roof system, but to substitute a polymer-modified cap sheet for the flood-coat and aggregate as a hybrid system.

In seismic regions, a mineral-surfaced cap sheet can be substituted for the aggregate surfacing. Cap sheet systems are lighter in weight, more reflective, and easier to inspect and repair than the aggregate systems, but require more positive drainage than the flood-coated systems. Where extremely high reflectivity is needed for hot climates, aggregate and mineral-surfaced systems can be field coated. Factory-coated cap sheets are also available.

Asphalt is easily dissolved in mineral spirits and, when solvent, fibers, and fillers are added, serves as the base for primer, roof coating (fibrated and non-fibrated) asphalt, plastic cement, and flashing mastic.

Asphalt can also be emulsified (dispersed in water) and aluminized to provide a reflective coating. Emulsified asphalt combined with glass yarns chopped at the spray gun provides a VOC-compliant system, used frequently on the West Coast. A reflective coating tops out the system.

While application of BUR is generally done with hot asphalt applied from a mop or asphalt spreader, there are self-adhering and solvent-based adhesive systems available as well.

Today, BUR is specified frequently as a re-cover system over an existing BUR system. The original aggregate surface is power-washed to remove dirt and loose aggregate; patches are made to the old membrane and wet areas removed to the deck. A re-cover board provides a smoother surface to receive the new roof system, or a ventilating base sheet can be spot attached. When new insulation is desired to upgrade the energy performance of the new roof, the new thermal insulation can be mechanically fastened or applied in hot bitumen, or low-rise foam adhesives can be used.

Sustainability and Maintainability

Where a building owner has familiarity with conventional asphalt roofing, BUR systems are easy to identify and repair. Once past warranty time, generic repair materials and coatings can easily extend roof life.

Drainage Requirements

While all roofing systems require slope to drain, coal-tar pitch in particular has been permitted on roofs with poor drainage. With vegetated roof systems, pitch may again prove to be a preferred waterproofing system, especially with its greater resistance to root penetration.

When re-covering an existing BUR, tapered insulation and/or addition of more roof drains in the low spots provide long-term solutions to ponding situations.

The Future of BUR

With more than a century of experience, there’s no question that bituminous roofing has proven performance. Challenges for providing a base for vegetated roofs, photoelectric systems, and heavily trafficked areas will require some adaptation, such as the use of MB flashings, pourable sealers, liquid-applied flashing systems, and certainly more attention to adequate drainage and preventative maintenance.

About the Author

Richard L. Fricklas

Richard (Dick) L. Fricklas received a Lifetime Achievement Award and fellowship from RCI in 2014 in recognition of his contributions to educating three generations of roofing professionals. A researcher, author, journalist, and educator, Fricklas retired as technical director emeritus of the Roofing Industry Educational Institute in 1996. He is co-author of The Manual of Low Slope Roofing Systems (now in its fourth edition) and taught roofing seminars at the University of Wisconsin, in addition to helping develop RCI curricula. His honors include the Outstanding Educator Award from RCI, William C. Cullen Award and Walter C. Voss Award from ASTM, the J. A. Piper Award from NRCA, and the James Q. McCawley Award from the MRCA. Dick holds honorary memberships in both ASTM and RCI Inc.