ROI from VFDs: Cutting Costs with Variable Frequency Drives

Variable frequency drives (VFDs) are an attractive energy management investment for your building’s motors. While VFDs have been around for years, they have become a mature and effective way to reduce the cost of running motors with variable torque loads, such as those used in HVAC systems.

Motors represent about 20 percent of all energy used in the United States and 65 percent of electrical usage in our manufacturing plants. Over the life of a motor in a three-shift manufacturing environment, the purchase cost is only 5 percent of lifecycle costs. The other 95 percent is energy used and a small amount for maintenance and repairs.

A reduction in speed produces more than straight-line savings due to the affinity laws that describe energy use in motors. In fact, a 20-percent reduction in motor speed produces a 50-percent energy savings. When you consider that most motors are oversized for their application, you see how large the opportunity is for energy savings. The ROI of a VFD investment is even more attractive if your local utility or state energy office offers demand-side management (DSM) rebates for VFDs. In addition, VFDs offer more precise control over HVAC systems.

The disproportionate benefits of controlling motor speed should be of interest to all building owners and managers. In addition to the energy savings, VFDs provide longer equipment life because systems are not running at 100 percent all the time. How long would your automobile last if it were driven 24/7 at race track speeds?

How Do VFDs Work?

Since alternating current (AC) does not reduce like direct current (DC), how does a VFD control speed?

In simple terms, the AC is turned into DC, and then turned back into AC, but with control over the power’s frequency. Although AC power is typically produced at 60 hertz (cycle/second), a VFD control reduces the frequency of the power, and thereby the motor speed, to match load requirements. While simple in concept, most VFD projects require an expert application engineer to apply the technology to variable load motors. Typical VFD applications in commercial buildings include:

- Air handling units

- Cooling tower fans

- Cooling tower pumps

- Circulation pumps for HVAC

- Chillers

- City-water booster pumps

- Compressed air systems.

How Much Can You Save?

Calculators from the DOE and VFD manufacturers can help you estimate the kWh savings and ROI of specific VFD applications. The first step is to determine the operating characteristics and cost of existing HVAC components. In the example below, a 100-horsepower pump with 10-percent reduction in speed yields a 27-percent reduction in annual operating cost.

|

100 HP MOTOR |

OPERATING COST/YEAR |

|

100% SPEED |

$27,139 |

|

90% SPEED |

$19,811 |

|

UTILITY SAVINGS |

$7,328 |

With this kind of information, an engineer identifies the best ROI opportunities.

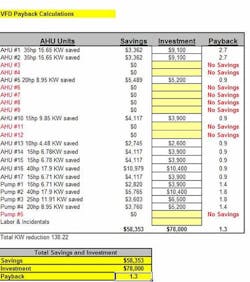

But what are real-world ROIs? It depends on the building. As the real-world chart below shows, VFDs provide an attractive ROI, but not all motors can justify them.

VFDs on Old Motors

Every motor and VFD drive salesman will recommend a new motor with premium efficiency for VFD applications. In general, this is a good idea due to better cooling and more copper in these motors. However, from a practical perspective, most VFD application engineers can extend the life of existing motors with proper VFD programming.

Most modern VFDs approach unity power factor (kW/kVA), so your building power factor should not be affected. Some electric utilities charge a small fee if your entire building’s power factor is below 85 percent.

Most modern VFDs also come with harmonic filtering to prevent the VFD from affecting a building’s power quality. Electronic equipment in buildings, such as personal computers and electronic lighting ballasts, should have a greater potential impact on power quality than VFDs. Additional benefits of VFDs are the elimination of across-the-line motor starters and longer life for V-belts and bearings.

An HVAC system running at 50-percent speed is also quieter, and varying the motor speed to match the space conditioning requirements improves energy savings and comfort better than the on/off cycling of old HVAC controls. In some older HVAC systems, energy usage actually went up when closing dampers in an attempt to throttle back motors.

Variable is good. ROI is great. Energy management is first and last an investment.

Richard G. Lubinski is president of Think Energy Management LLC (www.think-energy.net), an energy consulting firm. His national professional certifications include Certified Energy Manager, Certified Energy Auditor, Certified Demand Side Management Professional, Certified Sustainable Development Professional, Certified Energy Management Systems Contractor, Certified Business Energy Professional, and Certified U.S. Green Lights Survey Ally.