What a Water-Cooled HVAC System Can Do for Your Building

By Jerry Ackerman

Through its Climate Leaders program, the U.S. Environmental Protection Agency (EPA) works with organizations to develop long-term, comprehensive climate-change strategies. Setting corporate-wide greenhouse-gas (GHG) reduction goals is the first major step in implementing this process within your portfolio. The EPA's list of GHGs includes carbon dioxide (CO2), methane (CH4), nitrous acid (N2O), hydrofluorocarbons (HFCs), perflurocarbons (PFCs), and sulfur hexafluorides (SF6); CO2 is at the top of the list. In fact, CO2 emissions account for approximately 85 percent of GHG emissions in the United States.

In concert with EPA goals, the U.S. Green Building Council's LEED (Leadership in Energy and Environmental Design) program is in place to accomplish the goals of the green building movement: to reduce negative environmental impacts and implement best practices regarding the construction, operation, and management of buildings. LEED is an assessment system designed to evaluate energy efficiency and environmental performance from a whole-building perspective over the life-cycle of a building.

What is the relationship of these two initiatives to a building's cooling system? HVAC systems, which consume large amounts of energy, are significant contributors to GHG emissions. To help achieve both EPA and USGBC objectives, HVAC systems can be designed or retrofitted to reduce energy consumption, GHG emissions, water use, and environmentally hazardous circumstances.

How a Water-Cooled HVAC System WorksWater-Cooled or Air-Cooled HVAC Systems?

With respect to cooling systems in particular, there is a debate about which cooling methodology best meets EPA and USGBC objectives: water-cooled or air-cooled?

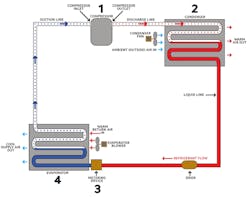

Cooling the condenser coil of a chiller plant can be accomplished by air cooling with a finned coil or water cooling with a cooling tower. Water-cooled condensers typically operate at a significantly lower head pressure and use much less energy. A study conducted by San Francisco-based Pacific Gas & Electric Co. (PG&E) showed that, in a typical 100,000-square-foot building in Fresno, CA, an air-cooled condenser system would use 440,000 kilowatt-hours (KWH) per year compared to 190,000 KWH per year for a water-cooled system. In other words, an air-cooled system requires 250,000 KWH more per year than a water-cooled system to perform the same cooling. These numbers result in an energy penalty of 130 percent over a water-cooled system. Several years ago, California changed its Title 24 regulation to require any building with more than 300 tons of cooling to use no more than 100 tons of air-cooled condensers. The driver for this regulation is energy savings. While first costs for an air-cooled system are lower, the PG&E study showed that life-cycle costs favor water-cooled systems.

The average U.S. power plant emits 1.55 pounds of CO2 for each KWH generated. Using the PG&E example, a significant reduction in GHG emissions can also be achieved: nearly 200 tons of CO2 each year. Since the 100,000-square-foot building described in the PG&E case is a relatively small commercial building, the overall reduction in CO2 emissions in many other cases could be substantially greater.

When comparing the two basic HVAC options, water-cooled systems are typically more energy efficient than air-cooled systems and support environmental efforts to reduce greenhouse-gas emissions.

How an Air-Cooled HVAC System WorksWhy the Reluctance to Use Water-Cooled Systems?

In spite of the benefits of water-cooled systems in terms of energy efficiency and GHG reduction, why do some building operators — even those in charge of green buildings — choose air-cooled condensers over water-cooled? Perceptions from some building operators and design engineers are among the reasons why air-cooled condensers are sometimes selected. It's thought that cooling towers use large quantities of water (and saving water is green), that water-cooled systems require much more maintenance than air-cooled, and that water treatment is difficult and environmentally unsound.

In terms of water usage, the PG&E study shows that a 100,000-square-foot building in Fresno, CA, with a water-cooled condenser would evaporate 576,985 gallons of water per year. Depending on the water quality and the treatment program being used, an additional 82,426 (at 8 cycles of concentration) to 144,246 (at 4 cycles) gallons of water must be blown down to prevent the deposition of mineral scale on equipment surfaces. Thus, the total water required to run this tower would be between 659,411 and 721,231 gallons per year. This water usage is usually compared to zero water required by an air-cooled system, which isn't necessarily a valid comparison. A study by the National Renewable Energy Laboratory (managed for the U.S. Department of Energy by the Midwest Research Institute and Battelle) determined that, on average, each KWH of energy generated in the United States consumes 2 gallons of water; therefore, an air-cooled system using 250,000 KWH more per year than a water-cooled system forces the utility to consume an additional 500,000 gallons of water per year. While water conservation still favors air-cooled systems, the margin is much smaller than you would assume without a thoughtful review.

In California and many other regions in the West, the water used for power generation is 4.42 gallons per KWH, slightly more than double the national average. Based on the PG&E example in California, the water-cooled system will consume between 659,411 and 721,231 gallons of water per year, while the air-based system will consume 1.105 million gallons of water per year due to its excess power consumption. In this case, the use of water cooling reduces water consumption by at least 35 percent.

In terms of maintenance, a cooling tower, like any other piece of equipment, requires it. Logically, an air-cooled condenser is not maintenance-free. Many air-cooled manufacturers recommend that at least once - and usually twice - per year, the coils on an air-cooled condenser be cleaned. Cleaning a 400-ton air-cooled condenser requires two people for 2 days and uses 10 to 20 gallons of concentrated, caustic chemical cleaners. Because of environmental concerns about these chemicals and the residue that is removed, many sites require that the 300 to 600 gallons of wastewater generated by this cleaning operation be collected and shipped to a hazardous waste site. In comparison, a water-cooled condenser should be cleaned once per year. This operation uses no chemicals and, for a 400-ton chiller, can be performed by two people in 1 day. The annual labor for cleaning a water-cooled condenser averages from 50- to 75-percent less than that required for cleaning an air-cooled condenser.

A 400-ton water-cooled system will have a condenser water pump, a back-up water pump, and one or two tower fans and one compressor - each of these components requires routine maintenance. Although a similarly sized air-cooled condenser system (two 200-ton units) typically has no water pumps, it usually contains about 20 condenser fans and eight compressors. Every fan and compressor requires routine maintenance; however, a water-cooled system has fewer components and typically requires less maintenance than an air-cooled system.

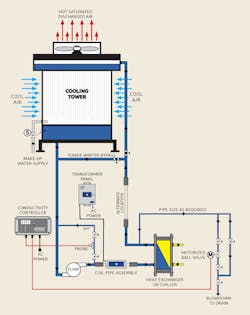

In terms of water treatment, a cooling tower uses water to transfer heat from the condenser and then evaporates a portion of that water to keep the water cool. An air-cooled condenser uses no water on-site and requires no on-site water treatment, while a water-cooled system (of any size) requires that the open loop be treated. Left untreated, the open loop can scale, corrode, and provide an encouraging environment for biological growth. To control this degradation, traditional water treatment uses a variety of mutually compromising chemicals. These chemicals interact with each other and must be periodically adjusted based on changes in load, make-up water, and ambient conditions. Many of the chemicals are hazardous in their concentrated form. There are environmental issues associated with drift, tower splash-out, spills, leaks, chemical air emissions, and blowdown. Chemical pump failures are common, and the overfeeding or underfeeding of any chemical can upset the delicate balance of the treatment. Once upset, the chemical systems are difficult to bring back into control.

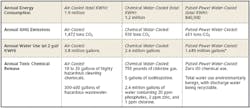

Air-Cooled HVAC and Water-Cooled HVAC with Pulsed-Power

Energy and Environmental Comparisons

(a 400-ton system at 3,120 operating hours/year)

This table compares air-cooled and water-cooled systems using national averages for a 400-ton cooling system. Note that each specific cooling system should be analyzed because of variances (mineral content of make-up water, system load, annual hours of operation, etc.) to determine site-specific energy savings, greenhouse-gas (GHG) reductions, water usage, and chemical elimination quantities.

* If the water discharged (blown down) is reused instead of water source supply use, total water use savings using pulsed-power technology would be another 420,000 gallons.

Pulsed-Power Water Treatment and EPA/USGBC Goals

Pulsed-power physical water treatment has changed the treatment of evaporative cooling systems. Pulsed-power uses pulsed, electric fields (a technology developed by the food industry for pasteurization) to control scaling, biological growth, and corrosion. This completely chemical-free approach to water treatment eliminates all of the environmental and health and safety issues associated with water treatment chemicals. Pulsed-power systems have no pumps to break down or chemical tanks to run dry; they are also forgiving of operational upsets and generally permit the operation of cooling towers at higher cycles of concentration (therefore, less blowdown and less water usage) than standard chemical treatment. Independent studies show that the method is not only effective for cooling towers, but that the performance of pulsed-power systems is also superior to standard chemical treatment in biological control and water usage. With the elimination of the problems associated with chemical water treatment, the advantages of water-cooled condensers make them an environmental, energy-efficient, and economic choice, dovetailing with the goals of both EPA and USGBC initiatives.

Electronics are used to reduce scale build-up of limestone in plumbing systems from calcium or magnesium carbonate in the water. Electronic systems produce a pulsed, time-varying, induced electric field inside a PVC pipe that is fit directly into the cooling tower's recirculating water system. The electric signal changes the way minerals in the water precipitate, totally avoiding hard limescale by instead producing a non-sticking mineral powder in the bulk water. This powder is readily filterable and mostly removed during normal blowdown, or it settles loosely in the cooling tower basin for easy annual removal. Bacteria are incorporated into this mineral powder and, therefore, leave the system by blowdown, filtration, or settling. The encapsulated bacteria (some of which were injured via electroporation on their membrane walls, causing cell lysis) cannot reproduce, resulting in an exceedingly low bacteria population. Water softening is not necessary (nor recommended) with this type of system treatment, and high cycles of concentration are usually obtainable, leading to significant water conservation. Based on the pulsed-power capability to eliminate biofilm (a slime layer with more than 4 times the insulating capacity of mineral scale), this technology saves a minimum of 5 percent in energy use compared to conventional chemical treatment operations.

Water-based cooling systems are typically treated with chemicals to prevent mineral scale formation, control biological activity, and inhibit corrosion. Chemical water treatment results in the chemicals or their toxic byproducts being released into the environment through leaks, water discharge (blowdown), air emissions, spills, spray, and drift. These chemical emissions are environmentally harmful. In a cooling tower, chlorine or some other biocide is commonly used to control biological activity and reduce pathogens. Most of the chlorine added to the system is rapidly discharged into the atmosphere as chlorine gas. Corrosion inhibitors such as zinc, silicates, molybdenates, and phosphates are discharged in the drift from the tower and spray, settling to the ground and through the sewer system with blowdown. Water softeners are often used to prevent scaling and, as part of the water-softening process, quantities of salt brine are discharged.

As part of a LEED-certified project involving a relatively small cooling system (400 tons or 1,200 gpm, operating 12 hours a day, 5 days a week - 3,120 hours per year), it was demonstrated that the use of pulsed-power water treatment eliminated the discharge of 1,145,644 gallons of chemically contaminated water (20 ppm phosphates, 2 ppm zinc, and 1 ppm chlorine and disinfection byproducts) as blowdown and drift, 4 to 5 gallons of isothiazoline, and 749.1 gallons of industrial-strength chlorine bleach. Much larger cooling systems have been quantified in the same way on other LEED projects, with the results understandably being orders of magnitude higher in scope.

With respect to the above project, in conjunction with typical cooling-tower characteristics as provided by the Houston-based Cooling Technology Institute (CTI), it can be calculated that 739.6 pounds or gallons of chlorine evaporate from this tower annually. Given the hours of operation and typical airflow from this tower, the chlorine concentration in the exiting air is 0.51 ppm. The level of chlorine discharge is significant: The OSHA short-term (15-minute) exposure limit is 1 ppm (3,000µg/m3) and the OSHA TWA PEL (8-hour average) is 0.5 ppm (1,500µg/m3).

As previously noted, the cooling-tower system for this building uses a 400-ton cooling-tower system with an estimated recirculation rate of 1,200 gpm. Using the rules of thumb provided by the CTI, it may be calculated that this system will, on an annual basis, evaporate 1,123,200 gallons of water, emit 22,464 gallons of water as drift, and blowdown 1,123,200 gallons of water if chemically treated (at 2 cycles of concentration), or 561,600 gallons of water if pulsed power treated (at 3 cycles of concentration), for a total annual water use of 2,268,864 gallons (under chemical treatment), or 1,707,264 gallons (under pulsed-power treatment). From this analysis, it is shown that the use of pulsed-power water treatment saves 561,100 gallons of water per year (that much less water being blown down), or approximately 50 percent of the total water blown down under chemical treatment (or 25 percent of the total water consumed under chemical treatment, less the amount of water attributed to drift). While the cycles of concentration vary from project to project because of various factors (system size, load, mineral content of the water, etc.), the water savings of pulsed-power technology over chemical treatment typically ranges from 15 percent to 45 percent before addressing the environmentally benign and recyclable attributes of the blowdown water discharged from a pulsed-power treated system, which, if recycled, can account for substantially more water savings.

On this project, the use of pulsed-power water treatment vs. traditional chemical water treatment provides environmental benefits and water savings. The quantities of chemicals that would have been released annually from the operation of the cooling tower under chemical treatment are:

- 739.6 pounds of chlorine gas.

- 4 to 5 gallons of isothiazoline via drift and blowdown.

- 1,145,644 gallons of contaminated water blowdown and drift containing 20 ppm phosphate, 2 ppm zinc, and 1 ppm chlorine (including disinfectant byproducts).

Reduction in total water consumption is calculated to be an annual water-usage savings of approximately 25 percent (or 561,600 gallons) when compared to a typical open system with conventional chemical treatment. An additional 561,600 gallons of water discharged (blown down) annually under pulsed-power technology is environmentally benign and has been recycled or reused (toilet flushing, lawn irrigation, etc.) on various sites, saving that many more gallons that will not have to be consumed via the water source (make-up water) supply. Total annual water use savings on a "holistic level" for this project could be 50 percent, or 1,123,200 gallons.

Given the previously cited standard (2 gallons of water are used to generate a KWH), the annual energy consumption for this project, using pulsed-power technology, uses 280,800 less KWH than chemical treatment (without accounting for the energy savings associated with the elimination of biofilm). Under pulsed-power technology, energy consumption could be reduced further in terms of blowdown water being reused in place of new make-up water being consumed.

Making a Decision

The considerable environmental benefits of pulsed-power technology, along with the substantial reduction in greenhouse-gas emissions through the application of water-cooled systems, contribute significantly toward the achievement of EPA and USGBC goals. When it's time for you to make a decision about air-cooled or water-cooled HVAC systems, weigh your options carefully and think about the benefits and drawbacks of each type of system.

This article was first written in 2008 and remains accurate as of 2018.