Tips for Selecting Rigid Roof Insulation

By Alvin Nunnikhoven

Specifying an insulation system that facilitates proper roof performance is fundamental, but is only one of the factors to keep in mind when it comes to roof insulation. Roof insulation selection must also consider the thermal needs of the building, satisfy applicable energy codes, and result in a roof assembly that is approved by the property insurance carrier.

Rigid insulation is a critical component to consider when selecting a low-slope roofing system for your building. The insulation layers become an integral part of the roof assembly and must function in concert with the roof membrane and the structural deck. Wise choices result in successful roof systems that perform over the long term. Poor choices can negatively impact roof performance, possibly within a short time after the roof's installation.

This article examines product options for roof insulation, methods of insulation attachment, and considerations for selecting a roof insulation system.

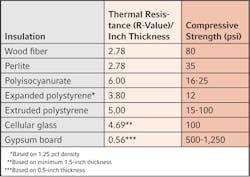

Insulation Thermal Resistance and Compression Strength ValuesProduct Options

A variety of rigid insulation types are available for use in today's roofing marketplace, including wood fiber, perlite, polyisocyanurate, polystyrene (expanded or extruded), cellular glass, gypsum board, and composites. Rigid glass fiber insulation is no longer manufactured or available for use in low-slope roofing systems.

Wood fiber is an organic insulation board composed of wood, cane, or vegetable fibers mixed with various types of fillers and binders. The insulation may be either asphalt impregnated or asphalt coated to enhance its moisture resistance. Uncoated insulation should be utilized where the selected roof covering is incompatible with asphalt-based coatings. Wood fiber insulation is only available in flat boards.

Perlite is an insulation board composed of inorganic expanded silicaceous volcanic glass (perlite) combined with organic fibers and binders. Air cells within the expanded perlite provide its insulating efficiency. The top surface of the insulation board is treated with either an asphalt coating or a proprietary coating. The coating is intended to limit adhesive (asphalt) absorption into the insulation during the roof membrane application. Perlite insulation is available in flat boards and tapered boards.

Polyisocyanurate is a closed-cell foamed plastic insulating core that is sandwiched between organic or inorganic felt facers, glass fiber mat facers, or glass-fiber-reinforced aluminum foil facers. A chlorine-free blowing agent (typically pentane) expands the foam material, creating the closed-cell structure. The closed-cell structure gives the insulation its high thermal resistance. Air diffusion into the insulation cell structure (over time) results in slight reduction of thermal resistance; however, its insulating efficiency remains higher than other rigid insulations (see the chart, above). Polyisocyanurate insulation is available in flat boards and tapered boards.

Polystyrene insulations are manufactured in two ways: expanded and extruded. Expanded polystyrene consists of the polystyrene polymer impregnated with a foaming agent. When exposed to heat, the material expands and is molded into a uniform, closed-cell insulating material. Expanded polystyrene is available in a variety of densities, ranging from 0.70 to 3 pounds per cubic foot (pcf); however, most roof covering manufacturers require a minimum density of 1.25 pcf. Expanded polystyrene insulation is available in flat boards and tapered boards.

Extruded polystyrene consists of a blended polystyrene polymer that is heated and run through an extrusion process. The material is then exposed to the atmospheric conditions, causing it to expand and create its closed-cell structure. Extruded polystyrene is also available in a variety of densities, ranging from 1.3 to 2.2 pounds pcf. Extruded polystyrene insulation is also available in flat boards and tapered boards.

Cellular glass insulation is composed of crushed glass combined with a foaming agent. The components are mixed, placed in a mold, and heated to a temperature of 950 degrees F. Heat melts the glass and decomposes the foaming agent, causing the mixture to expand within the mold, creating uniform, connected closed cells to form the insulating material. Cellular glass insulation is available in flat boards and tapered boards, as well as in flat blocks and tapered blocks.

Gypsum board is a nonstructural, noncombustible, water-resistant, treated gypsum core panel. The water-resistant gypsum core may be manufactured with or without glass mat facers. The board is available with a proprietary, non-asphaltic coating on one side to enhance roof membrane adhesion. Gypsum board is typically used as a cover board over foam plastic insulations, as a thermal barrier over a steel deck, or as a vapor retarder substrate.

Composite insulation boards consist of multiple layers of insulation that are factory laminated together for specialty purposes. Examples of composite insulations include expanded polystyrene/wood fiber, etc.

Insulation Attachment

Insulation must be properly secured to the roof deck to provide an acceptable substrate for the roof covering. Insulation attachment options include:

- Mechanical fastening.

- Hot asphalt adhesion.

- Low-rise polyurethane adhesives.

- Loose laid with ballast.

On steel and wood roof decks, mechanical fastening with self-tapping screws and plates is the most common and approved method for insulation attachment. Mechanical fastening is also acceptable on other deck types (such as cast-in-place concrete, cementitious wood fiber, and gypsum); however, mechanical fastening requires pre-drilling pilot holes and the use of specialty fasteners for insulation attachment. The additional labor associated with pre-drilling, potential deck damage, and the noise disruption to interior building operations leaves mechanical fastening less desirable when compared to other attachment options when fastening to decks other than steel or wood.

Hot asphalt is an approved method for insulation attachment on concrete roof decks and over mechanically attached base sheets on nailable decks such as gypsum, wood, cementitious wood fiber, and lightweight concrete. Hot asphalt is also acceptable for adhering a cover board or subsequent insulation layers over a mechanically fastened base layer of insulation. Hot asphalt is not approved for insulation attachment directly to steel decks.

Low-rise polyurethane adhesives are approved and can be substituted for hot asphalt to provide insulation attachment. Polyurethane adhesives are advantageous for use where asphalt odors are objectionable or asphalt delivery to the roof is impractical. Polyurethane adhesives are applied as either full coverage or as bead/ribbon installations. Bead-applied adhesive is placed in 0.75- to 1-inch ribbons over the substrate. Bead spacing is typically 12 inches on center in the field of the roof, with increased bead spacings (6 inches and 4 inches) in the roof perimeters and corners, respectively. Polyurethane adhesives are not approved by FM Global (a provider of commercial and industrial property insurance, engineering-driven underwriting and risk-management solutions, and property-loss-prevention research) for insulation attachment directly to steel decks; however, polyurethane adhesive, in conjunction with mechanical fastening on steel decks, is approved for use and required to achieve the higher wind-uplift resistances in hurricane-prone regions.

In a ballasted roof system, the insulation and roof membrane are typically loose laid and then covered with the weight of washed river gravel or concrete pavers. The required weight of the ballast varies by wind zone, but, at a minimum, is 10 to 12 pounds per square foot in the field of the roof, increasing at the roof perimeters and corners. Ballasted assemblies are not allowed in high wind zones and various municipalities throughout the United States.

ASHRAE 90.1 Climate ZonesMaking a Selection

Selecting a roof insulation product cannot be isolated because the choice generally needs to be made in close connection with the membrane type and application method. Consider selecting an insulation product that includes:

- Membrane compatibility.

- Energy code (R-value requirements).

- Insurance and code requirements regarding wind and fire.

- Strength (more specifically, compressive strength for traffic and hail resistance).

Not all insulation types are compatible with all roof covering types. For instance, expanded and extruded polystyrenes should not be in direct contact with thermoplastic PVC single-ply membranes. When in direct contact, plasticizer migration occurs, causing the PVC membrane to become brittle. Modified bitumen membranes, as well as conventional built-up membranes, are not recommended for direct application over foam plastic insulation boards. Cover board insulation is recommended and required by modified bitumen and built-up roof covering manufacturers when utilizing foam plastic insulations. Wood fiber, perlite, and gypsum board are the most common cover board insulations in use today.

State and local building codes have requirements for insulation thermal resistances. Forty-seven states, as well as Washington, D.C., have adopted the Intl. Building Code (IBC). Chapter 13: Energy Efficiency of the IBC, in turn, references the Intl. Energy Conservation Code (IECC). The IECC has adopted the ASHRAE 90.1-2004, Energy Standard for Buildings Except Low-Rise Residential Buildings as a reference standard. The ASHRAE 90.1 standard separates the United States into eight climate zones, with Zone 1 being the hottest and Zone 8 being the coldest. The figure above (labeled ASHRAE 90.1 Climate Zones) illustrates the climate zones.

Based on the climate zones, the standard also lists the recommended thermal resistance for continuous insulation located above the roof deck. It should be noted that ASHRAE has proposed increases to the minimum required roof insulation levels in the standard. As of press time, the proposed changes were approved by the ASHRAE Standard Committee and are awaiting the next update to IBC and IECC, scheduled for 2009.

A basic understanding of available insulation types and the code requirements for insulation thermal resistance is essential before selecting the type of insulation to use under a roof covering. For example, a required insulation thermal resistance for a commercial building located in Zone 6 on the climate zone map is 20. From the chart above, you can roughly calculate the insulation thickness to meet the thermal resistance as follows:

- Wood fiber = 7.5 inches.

- Perlite = 7.5 inches.

- Polyisocyanurate = 3.3 inches.

- Expanded polystyrene = 5.3 inches.

- Extruded polystyrene = 4 inches.

- Cellular glass = 4.5 inches.

- Composite (polyisocyanurate/wood fiber, perlite, or gypsum board) = 3.5 inches.

Due to composition, greater insulation thicknesses are required for wood fiber and perlite when compared with polyisocyanurate or composites. Before selecting insulation, it is important to understand the impact the insulation thickness can have on the roof installation. For example, perimeter wood blocking, roof curbs, or rooftop-equipment elevations may need to be raised as roof insulation thickness increases.

Insurance requirements also need to be taken into consideration when selecting the roof insulation to be used. Many properties are insured by an FM Global affiliate or an insurance company that requires use of FM Global-tested and -approved roof assemblies. Approvals for tested assemblies are very specific regarding the types, thicknesses, configurations, attachments, and acceptable manufacturers of roof insulation. FM-approved assemblies are researched using RoofNav, FM Global's Web-based database and search engine.

Another important factor to consider is the existing deck type and whether the insulation is approved for application over a particular deck type. Building codes permit the direct application of foam plastic insulations (polyisocyanurate, expanded polystyrene, and extruded polystyrene) over steel roof decks, provided that the insulation manufacturer has tested and passed either the UL 1256 Standard for Fire Test of Roof Deck Constructions or FM 4450 Approval Standard for Class 1 Insulated Steel Roof Decks test. A thermal barrier, either 0.75-inch perlite insulation or 5/8-inch gypsum board, is required beneath the foam plastic insulation if the manufacturer has not passed either of these tests. The building owner should also check with the insurance carrier since FM Global does not approve the direct application of expanded or extruded polystyrene insulations over steel decks.

Concentrated roof traffic can be as hard on a roof system as any other factor. It is not uncommon to see collapsed roof insulation where traffic (particularly wheel and equipment loads) is heavy. Compressive strength should be evaluated closely based on the anticipated traffic loads. Oftentimes, a combination of insulations is used to best address multiple selection criteria. As an example, polyisocyanurate is often used as the base layer of insulation due to its high R-value and code approvals, in combination with a gypsum cover board, which enhances the system's compressive strength and ability to withstand traffic loads and hail events. Selecting two layers of insulation with staggered joints is also advantageous since the system strength is enhanced and thermal shorts are reduced.

Selecting the right insulation product and application method is fundamental to the design of an appropriate roof system. While there are a variety of insulations available for use in today's low-slope roofing market, understanding the product options, application methods, and selection criteria will ease the selection process.

Alvin Nunnikhoven is a registered roof consultant (RRC) and senior consultant at Benchmark Inc. (www.benchmark-inc.com), Cedar Rapids, IA.

Roof Insulation and Reflectivity Cut Costs